The new generation of ribbon slitting machine supports one-click switching of multiple materials and widths

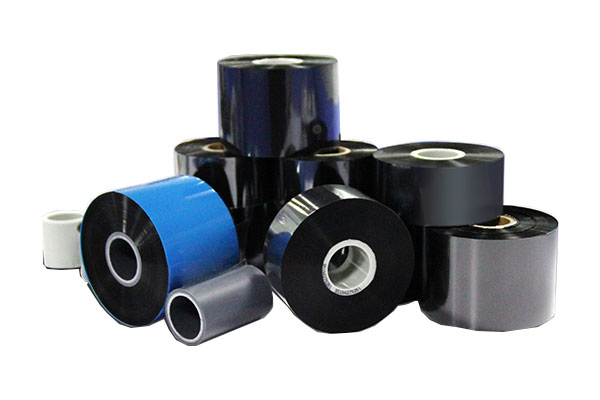

Through intelligent upgrades, the new generation of ribbon slitting machine can indeed realize one-key rapid switching of multiple materials (such as wax-based, mixed-based, resin-based ribbons) and multi-width specifications, significantly improving production efficiency and flexibility. The following is a detailed description of its core functions and technical features:

1. Multi-material compatibility

• Adaptive tension control: High-precision servo motor with closed-loop tension system is used to automatically adjust the tension requirements of different materials (wax-based/mixed-based/resin-based) to avoid breakage or crimping.

• Temperature compensation technology: For resin-based ribbons with high melting points, the slitting head is equipped with a dynamic temperature control module to reduce the sticking problem caused by heat accumulation.

• Material recognition system: RFID or visual recognition module can be selected to automatically read the ribbon roll label and call the preset parameters to reduce manual setting errors.

2. One-click switching of multiple widths

• Modular turret design: With the quick-change toolholder structure and the electric adjustment mechanism, the width can be changed in less than 30 seconds (e.g. from 80mm to 50mm).

• Intelligent calibration function: the machine automatically memorizes common specifications (such as 10mm/20mm/30mm, etc.), and directly calls it through the HMI interface, with an accuracy of ±0.1mm.

• On-line detection feedback: Integrated laser width gauge, real-time monitoring of slitting width and automatic deviation correction to ensure slitting consistency.

3. Intelligent control system

• Central integrated panel: The touch screen integrates PLC control, supports recipe management (storing ≥ 100 sets of parameters), and automatically loads the corresponding speed, tension, temperature and other parameters when switching.

• Remote maintenance interface: Support IoT connection to achieve fault warning, consumables life monitoring, and remote debugging to reduce downtime.

4. Improved efficiency and stability

• High-speed slitting capacity: the maximum linear speed can reach 300m/min (depending on the material), and it is equipped with an electrostatic eliminator to ensure the uniformity of winding at high speed.

• Automatic recycling of waste edges: independent scrap coiling device reduces the frequency of manual cleaning and keeps the working environment clean.

5. Application scenario expansion

• Customized production of small batches: The ability to quickly switch is especially suitable for the needs of multi-variety and small orders in the label printing industry.

• Compatible with special materials: optional low-friction guide roller assembly for slitting unbacked ribbons or anti-counterfeiting special ribbons.

Optional upgrades

• Visual sorting robotic arm: linked with the slitting machine to realize automatic classification and palletizing according to specifications after slitting.

• MES system docking: Realize the automatic upload of production data (meters, yield rate, etc.) to the factory management system.

This type of equipment usually needs to be customized according to specific production needs (e.g., maximum coil diameter, slitting accuracy class, etc.), and it is recommended to provide a detailed bill of materials and capacity targets to optimize the solution.

Recent Post

Customized slitting solutions: How can ribbon slitting machines meet the needs of different industries?15. April, 2025

Customized slitting solutions: How can ribbon slitting machines meet the needs of different industries?15. April, 2025 How does the ribbon slitting machine achieve micron slitting? Key technologies are all revealed14. April, 2025

How does the ribbon slitting machine achieve micron slitting? Key technologies are all revealed14. April, 2025 The five core functions of the high-precision ribbon slitting machine improve the efficiency of label production12. April, 2025

The five core functions of the high-precision ribbon slitting machine improve the efficiency of label production12. April, 2025 Analysis of the core function of the ribbon slitting machine: the perfect combination of precise slitting and efficient production11. April, 2025

Analysis of the core function of the ribbon slitting machine: the perfect combination of precise slitting and efficient production11. April, 2025

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Paper Core Loading Machine

Paper Core Loading Machine Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2