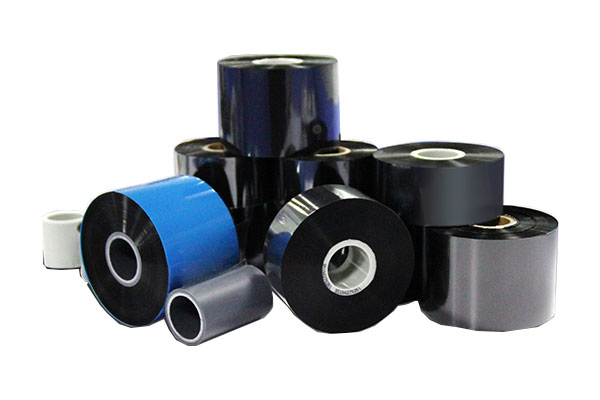

Specially designed for high-end ribbons: the slitter is precisely adapted to wax-based/resin-based/mixed-based materials

1. Industry pain points and solutions

Current challenges in ribbon slitting

• Large differences in material properties: wax-based, resin-based, and mixed-based ribbons have different requirements for slitting

• Edge burr problem: The traditional slitting method is easy to cause damage to the edge of the ribbon

• Tension control challenge: Different substrates have significant differences in tension sensitivity

• Static interference: Static electricity is easy to occur during the slitting process, which affects the printing quality

Advantages of professional slitting solutions

✔ The intelligent material identification system automatically adjusts the slitting parameters

✔ Nano-scale precision cutting ensures smooth edges without burrs

✔ The multi-stage tension control system adapts to the needs of different substrates

✔ The static elimination device ensures the cleanliness of the ribbon surface

Second, the core technology breakthrough

1. Intelligent slitting mode switching

| Ribbon type | Slitting features | Technical solutions |

| Wax-based ribbons | Soft and easy to stretch | Low tension + fast slitting |

| Resin-based ribbons | High hardness and easy brittleness | Constant temperature slitting + slow cutting |

| Mixed-base ribbons | Complex features | Adaptive adjustment system |

2. Precision slitting system

• Diamond-coated inserts: 3 times longer service life

• Laser-assisted positioning: slitting accuracy±0.05mm

• Real-time thickness monitoring: automatically compensates for thickness deviations

3. Environmental control system

• Constant temperature slitting chamber (18-25°C adjustable)

• Automatic humidity adjustment (40-60%RH)

• Class 1000 clean environment

Third, the application value embodiment

1. Quality improvement

• 50% higher slitting flatness

• 30% longer ribbon print life

• Defect rate reduced to less than 0.3%.

2. Efficiency optimization

• Changeover time reduced to 3 minutes

• Production speed up to 800m/min

• Support 24-hour continuous production

3. Cost control

• Material utilization rate of 99.2%

• 25% reduction in energy consumption

• 40% reduction in maintenance costs

Fourth, industry application cases

Electronic tag field

• Successfully cut 0.5mm ultra-narrow RFID ribbon

• Achieve million-level mass production with zero complaints

High-end packaging field

• Completed the slitting of special metallic ribbons

• Break through the composite materials that traditional slitters cannot handle

Medical labeling field

• Biocompatible certified slitting scheme

• Meet the requirements of aseptic environment production

5. Future technology prospects

1. AI intelligent optimization system

• Self-learning of different ribbon characteristics

• Automatically generate the optimal slitting scheme

2. IoT remote O&M

• Real-time equipment status monitoring

• Predictive maintenance alerts

3. Green manufacturing upgrades

• Scrap recycling systems

• Zero-emission slitting process

Precise slitting, defining a new standard for ribbons!

(More detailed technical parameters and customized solutions can be provided according to specific needs)

Recent Post

Customized slitting solutions: How can ribbon slitting machines meet the needs of different industries?15. April, 2025

Customized slitting solutions: How can ribbon slitting machines meet the needs of different industries?15. April, 2025 How does the ribbon slitting machine achieve micron slitting? Key technologies are all revealed14. April, 2025

How does the ribbon slitting machine achieve micron slitting? Key technologies are all revealed14. April, 2025 The five core functions of the high-precision ribbon slitting machine improve the efficiency of label production12. April, 2025

The five core functions of the high-precision ribbon slitting machine improve the efficiency of label production12. April, 2025 Analysis of the core function of the ribbon slitting machine: the perfect combination of precise slitting and efficient production11. April, 2025

Analysis of the core function of the ribbon slitting machine: the perfect combination of precise slitting and efficient production11. April, 2025

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Paper Core Loading Machine

Paper Core Loading Machine Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2