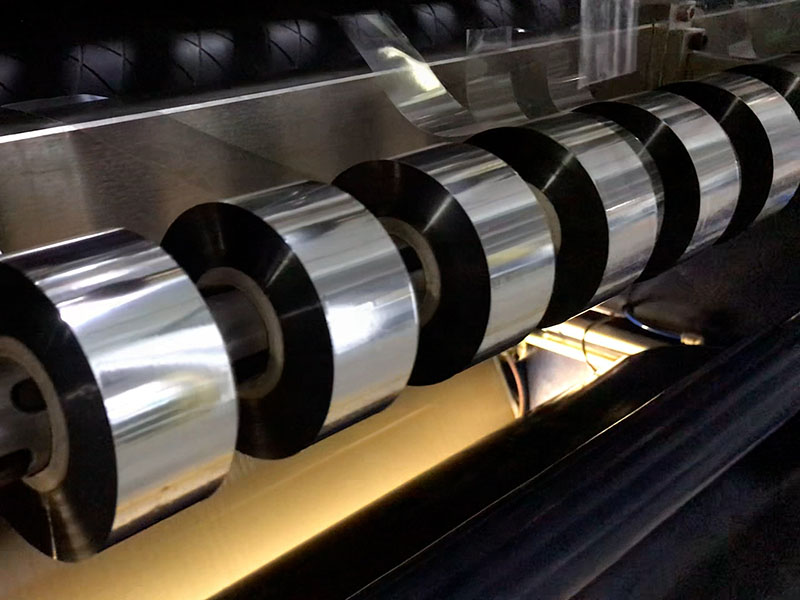

High-efficiency ribbon slitting machine: a powerful tool to improve production efficiency

The high-efficiency ribbon slitting machine is a high-precision equipment specially designed for ribbon production, which can significantly improve production efficiency and ensure product quality. Here are its key features and benefits:

1. High-precision slitting

• Precise cutting: Advanced control system and high-precision tools are used to ensure accurate slitting size and minimal error.

• Multiple specifications: support the slitting needs of different widths and lengths, and adapt to diversified production.

2. Efficient production

• Fast slitting: high-speed operation, greatly increasing production capacity and shortening delivery time.

• Automated operation: high degree of automation, reduce manual intervention, and reduce error rate.

3. Stable and reliable

• High-quality materials: Wear-resistant materials are used for key components to extend the life of the equipment.

• Stable operation: The design is reasonable to ensure long-term stable operation and reduce failures.

4. Easy to operate

• User-friendly: The interface is intuitive, simple to operate, and easy to use.

• Easy maintenance: Modular design, easy maintenance and replacement of parts.

5. Energy saving and environmental protection

• Energy-saving design: Optimize energy consumption and reduce production costs.

• Eco-friendly materials: meet environmental standards and reduce environmental impact.

6. Widely used

• Applicable to multiple industries: suitable for labeling, packaging, electronics and other industries.

• Wide range of materials: not only ribbons, but also other similar materials.

summary

Through high precision, high efficiency, stability and ease of operation, the high-efficiency ribbon slitting machine has become a powerful tool to improve production efficiency and help enterprises improve their competitiveness.

Recent Post

Ribbon slitter is an efficient solution to reduce consumables waste26. April, 2025

Ribbon slitter is an efficient solution to reduce consumables waste26. April, 2025 From industrial to medical: ribbon slitters are versatile in many fields24. April, 2025

From industrial to medical: ribbon slitters are versatile in many fields24. April, 2025 One-button operation: How can ribbon slitter simplify the production process?17. April, 2025

One-button operation: How can ribbon slitter simplify the production process?17. April, 2025 Why Choose Automatic Ribbon Slitting Machine? Precision, speed and stability16. April, 2025

Why Choose Automatic Ribbon Slitting Machine? Precision, speed and stability16. April, 2025

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Paper Core Loading Machine

Paper Core Loading Machine Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2