Automatic slitting machine: intelligent operation, precise cutting

First, overview

Automatic slitting machine is an efficient and intelligent equipment, which is widely used in packaging, printing, labeling and other industries to cut wide materials into narrow strips of required width. Its core features are intelligent operation and precise cutting, which can significantly improve production efficiency and slitting quality.

Second, the working principle

1. Automatic unwinding

◦ The material roll is placed on the unwinding reel, and the appropriate tension is maintained by the automatic tension control system to ensure that the material unfolds smoothly.

2. Automatic deviation correction

◦ When the material enters the automatic deviation correction system, the photoelectric sensor detects the edge position and automatically adjusts the material position to ensure that the edge is neat when slitting.

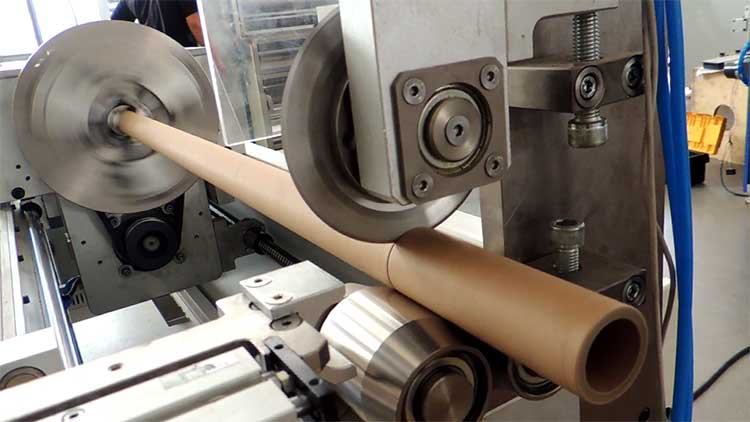

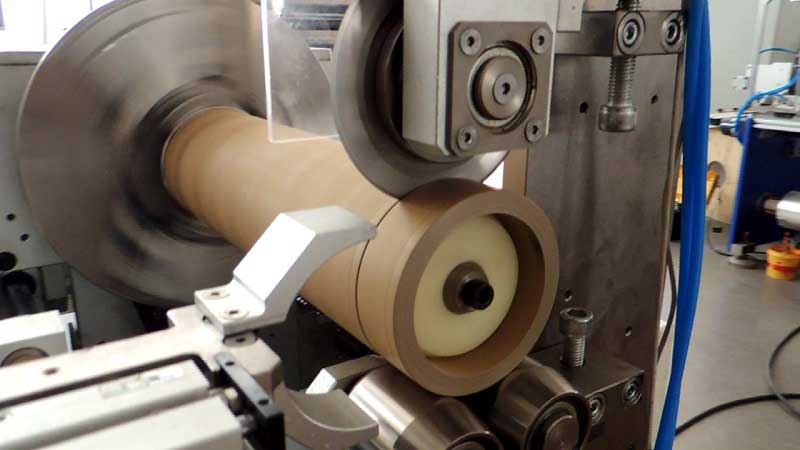

3. Precise slitting

◦ The material is slitted according to the preset width through a high-precision slitting tool. The slitting methods include round knife slitting and straight knife slitting, the round knife is suitable for high-speed slitting, and the straight knife is suitable for high-precision slitting.

4. Automatic winding

◦ The narrow strip after slitting is wound by an automatic winding shaft, and the winding tension is kept constant by the control system to ensure that the winding is neat.

5. Intelligent detection and control

◦ During the whole process, the intelligent detection system monitors the slitting quality in real time, and automatically alarms or stops the machine when defects are found. The intelligent control system coordinates the operation of each component to ensure slitting accuracy and efficiency.

Third, performance characteristics

1. Intelligent operation

◦ Automatic roll change: Automatically identify the replacement of material rolls to achieve seamless splicing and reduce downtime.

◦ Automatic tool adjustment: Automatically adjust the tool position according to the preset width to ensure the slitting accuracy.

◦ Automatic detection: Real-time detection of slitting quality through sensors and vision systems, automatic adjustment of parameters.

2. Precise cutting

◦ High-precision tools: high-hardness blades and automatic sharpening systems are used to ensure smooth and burr-free slitting edges.

◦ High-precision web tracking: The photoelectric web guiding system ensures that the edges of the material are aligned and the slitting width is consistent.

3. Efficient production

◦ High-speed slitting: Servo motor drive and precision transmission system are used to achieve high-speed slitting and improve production efficiency.

◦ Continuous production: Automatic roll change and splicing systems ensure continuous production and reduce downtime.

4. Stable and reliable

◦ Tension control: The closed-loop tension control system ensures that the material tension is constant and avoids deformation or breakage.

◦ Environmental adaptability: temperature and humidity control and dustproof measures ensure the stable operation of the equipment in different environments.

5. Easy to operate

◦ Human-machine interface: set parameters and monitor the operation status through the touch screen, which is simple and intuitive to operate.

◦ Remote monitoring: Support remote monitoring and fault diagnosis to improve maintenance efficiency.

6. Energy saving and environmental protection

◦ Energy-saving design: Adopt high-efficiency motor and energy-saving control system to reduce energy consumption.

◦ Eco-friendly materials: Made with eco-friendly materials to reduce the impact on the environment.

Fourth, the field of application

Fully automatic slitting machines are widely used in packaging, printing, labeling, electronics, medical and other industries, and are suitable for high-precision slitting of film, paper, non-woven fabrics, composite materials and other materials.

Fifth, summary

The automatic slitting machine has significantly improved the production efficiency and slitting quality through intelligent operation and precise cutting. Its high efficiency, stability, simplicity and environmental protection make it an indispensable equipment in modern industrial production.

Recent Post

Detailed explanation of the multi-specification adaptation and flexible cutting function of the paper tube cutter27. April, 2025

Detailed explanation of the multi-specification adaptation and flexible cutting function of the paper tube cutter27. April, 2025 Customized paper cutting tube machine: to meet the special needs of different industries26. April, 2025

Customized paper cutting tube machine: to meet the special needs of different industries26. April, 2025 How does the automatic paper tube cutter improve production efficiency?23. April, 2025

How does the automatic paper tube cutter improve production efficiency?23. April, 2025 Automatic slitter: a key function to improve production efficiency22. April, 2025

Automatic slitter: a key function to improve production efficiency22. April, 2025

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Paper Core Loading Machine

Paper Core Loading Machine Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2