Improvement and optimization of cutting accuracy of slitting machine

The cutting accuracy of the slitting machine directly affects the product quality and production efficiency, and improving and optimizing the cutting accuracy is the key goal of the design and use of the slitting machine. The following are the main methods and optimization measures to improve the cutting accuracy of the slitting machine:

1. Optimization of mechanical structure

• High rigidity body: The use of high-strength materials and optimized structural design to reduce vibration and deformation during equipment operation.

• Precision guide rail and drive system: The use of high-precision linear guide rails and ball screws ensures the smooth movement of the cutting head.

• High-precision tools: Choose high-quality tools, and regularly maintain and replace them to ensure tool sharpness and geometric accuracy.

2. Drive and control technology

• Servo motor drive: High-precision servo motor is used to achieve precise speed and position control.

• Closed-loop control system: real-time feedback of position information through encoders and sensors to achieve closed-loop control and improve cutting accuracy.

• Multi-axis linkage control: Optimize the multi-axis cooperative motion algorithm to ensure the synchronization and stability of each axis movement during the cutting process.

3. Material tension control

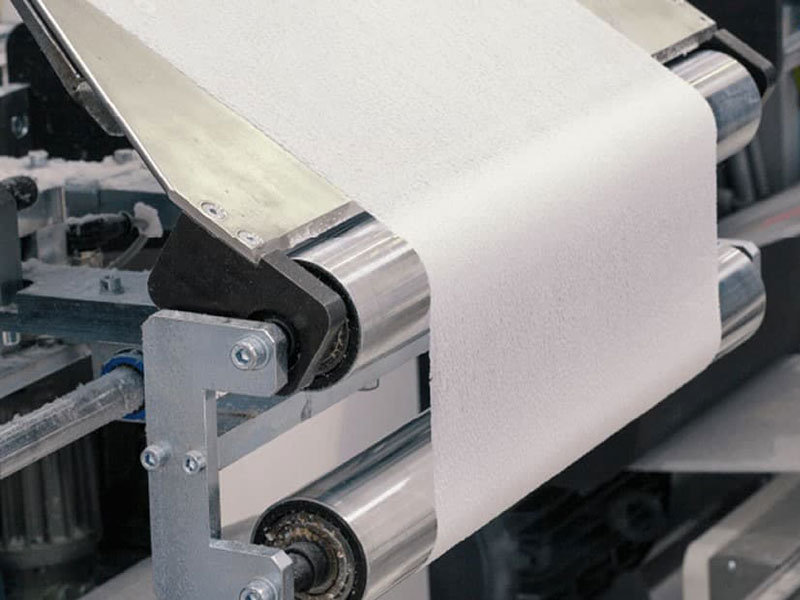

• Constant tension control: The automatic tension control system is adopted to ensure that the tension of the material is constant during the slitting process, and to avoid the cutting error caused by tension fluctuation.

• Tension sensor: Install a high-precision tension sensor to monitor and adjust the material tension in real time.

4. Optimization of cutting parameters

• Speed & Pressure Matching: Adjust the cutting speed and pressure according to the material properties to avoid poor cutting due to parameter mismatch.

• Dynamic adjustment: Adjust the cutting parameters in real time through the intelligent system to adapt to different materials and working conditions.

5. Intelligence and automation

• Visual Recognition System: Integrate machine vision system to automatically identify material edges and defects for precise positioning and cutting.

• Automatic deviation correction system: detect the position of the material through the sensor, and automatically adjust the cutting position to ensure the cutting accuracy.

• Intelligent Algorithms: Optimize cutting paths and parameters with artificial intelligence algorithms to improve cutting accuracy and efficiency.

6. Environmental control

• Temperature and humidity control: Operate the slitting machine in a constant temperature and humidity environment to reduce the impact of environmental factors on the accuracy of the equipment.

• Anti-vibration measures: Install vibration damping devices or choose a low-vibration environment to reduce the impact of external vibration on cutting accuracy.

7. Operation and Maintenance

• Operation training: professional training for operators to ensure the correct use of equipment and avoid human error.

• Periodic Calibration: Calibrate the equipment regularly to ensure that the components are in the best condition.

• Maintenance: Regularly clean, lubricate and inspect the equipment, replace worn parts in time, and maintain the accuracy of the equipment.

8. Adaptation of material properties

• Material pretreatment: Pretreatment of the material (such as leveling, destaticing, etc.) to reduce the influence of the material itself on the cutting accuracy.

• Slitting process optimization: Optimize the slitting process according to material characteristics (such as thickness, hardness, elasticity, etc.) to improve cutting accuracy.

9. Technological innovation

• Laser slitting technology: Laser cutting technology is used to achieve high-precision, non-contact cutting, which is suitable for materials with high precision requirements.

• Ultrasonic slitting technology: use ultrasonic vibration cutting to reduce material deformation and burrs, and improve cutting quality.

• Waterjet cutting technology: suitable for high-precision cutting of special materials, reducing the heat-affected zone.

10. Data Analysis and Optimization

• Data collection and analysis: Collect data from the cutting process through sensors and IoT technology to analyze the factors that affect accuracy.

• Continuous improvement: Continuously optimize equipment performance and cutting processes based on data analysis results.

summary

To improve the cutting accuracy of the slitting machine, it is necessary to start from many aspects such as mechanical structure, drive control, material tension, intelligent technology, environmental control, operation and maintenance. Through technological innovation and continuous optimization, the cutting accuracy of the slitting machine can be significantly improved, meeting the needs of high-precision production, and improving product quality and production efficiency.

Recent Post

Technical analysis of high-precision slitting machine for label and tape slitting27. April, 2025

Technical analysis of high-precision slitting machine for label and tape slitting27. April, 2025 Efficient solutions for nonwovens slitting: a detailed explanation of the industrial application of slitting machines27. April, 2025

Efficient solutions for nonwovens slitting: a detailed explanation of the industrial application of slitting machines27. April, 2025 How does a film slitting machine reduce waste? Efficient slitting technology to reduce losses26. April, 2025

How does a film slitting machine reduce waste? Efficient slitting technology to reduce losses26. April, 2025 Ribbon slitter is an efficient solution to reduce consumables waste26. April, 2025

Ribbon slitter is an efficient solution to reduce consumables waste26. April, 2025

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Paper Core Loading Machine

Paper Core Loading Machine Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2