Precise cutting, efficient production – discover the endless possibilities of slitter machines

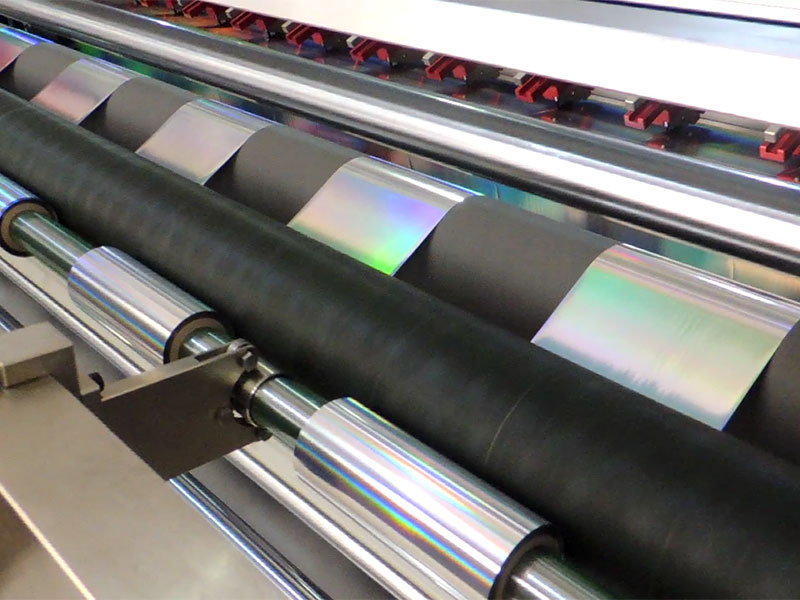

In the wave of modern industrial production, the slitting machine has become an indispensable right-hand man in many industries with its efficient and accurate cutting ability. Whether it is paper, plastic, film, metal, fabric and other diverse materials, the slitter can meet a variety of complex cutting needs with excellent performance, helping enterprises achieve efficient production and quality control.

1. Technological innovation, leading the industry trend

The slitting machine continues to integrate cutting-edge technology, and realizes the ultimate improvement of cutting accuracy through intelligent control system, high-precision sensors and advanced cutting technology. Whether it's automatically adjusting the cutting speed or monitoring the cut quality in real time, the slitter intelligently ensures that every cut achieves the best results. At the same time, the tool system of the slitting machine has also undergone many innovations, using high-quality alloy materials, combined with precision manufacturing processes, which greatly improves the durability and cutting efficiency of the tools.

2. Widely used to meet diverse needs

The slitting machine has a wide range of applications, from packaging, printing to electronics, construction, to textile, metal processing and other industries. In the packaging industry, the slitting machine can accurately cut various packaging materials to ensure the beauty and quality of packaged products; In the electronics industry, slitting machines can cut out precision electronic components to meet the requirements of high precision and high quality for electronic products. In addition, the slitter can also be customized according to the specific needs of customers to meet the diversified production needs.

3. Efficient production and reduced operating costs

The efficient cutting capacity of the slitting machine not only improves the production efficiency, but also greatly reduces the operating cost of the enterprise. Through the automatic control system, the slitter is able to achieve continuous and stable cutting operations, reducing manual intervention and downtime. At the same time, the intelligent management system of the slitting machine can monitor the status of the equipment in real time, warn potential faults in advance, and ensure that the equipment is always in the best working condition. These advantages make the slitter an important tool for enterprises to improve production efficiency and reduce operating costs.

4. Environmental protection and energy saving, to help sustainable development

With the increasing awareness of environmental protection, slitting machines also pay more attention to environmental protection and energy saving in the design and manufacturing process. The use of low-energy motors, optimization of the cutting process, reduction of waste generation and other measures make the slitter meet the needs of efficient production while also achieving environmentally friendly protection. This is not only in line with corporate social responsibility, but also provides strong support for the sustainable development of enterprises.

epilogue

As a powerful assistant in modern industrial production, the slitting machine provides a strong guarantee for the efficient production, quality control and sustainable development of the enterprise with its excellent performance and wide range of application fields. With the continuous progress of science and technology and the continuous changes of the market, the slitting machine will continue to innovate and develop, bringing more surprises and possibilities to more industries. Let's work together to explore the infinite possibilities of slitting machines and create a better future!

The purpose of this article is to comprehensively introduce the advantages of technological innovation, wide application, efficient production, environmental protection and energy saving of slitting machines, and at the same time look forward to its future development prospects. We hope this copy meets your needs, so please feel free to let us know if there are any adjustments or additions that need to be made.

Recent Post

An overview of the slitter's functions: from basic operations to advanced cutting techniques19. April, 2025

An overview of the slitter's functions: from basic operations to advanced cutting techniques19. April, 2025 Industry adaptability of slitter machine: a wide range of uses from packaging to new energy19. April, 2025

Industry adaptability of slitter machine: a wide range of uses from packaging to new energy19. April, 2025 One-button operation: How can ribbon slitter simplify the production process?17. April, 2025

One-button operation: How can ribbon slitter simplify the production process?17. April, 2025 Specially designed for high-end ribbons: the slitter is precisely adapted to wax-based/resin-based/mixed-based materials08. April, 2025

Specially designed for high-end ribbons: the slitter is precisely adapted to wax-based/resin-based/mixed-based materials08. April, 2025

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Paper Core Loading Machine

Paper Core Loading Machine Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2