08. January, 2025delish0

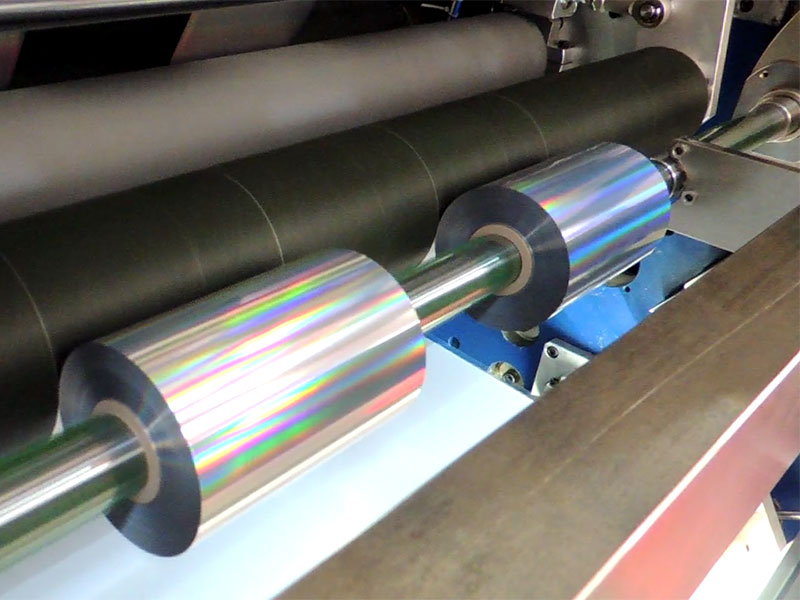

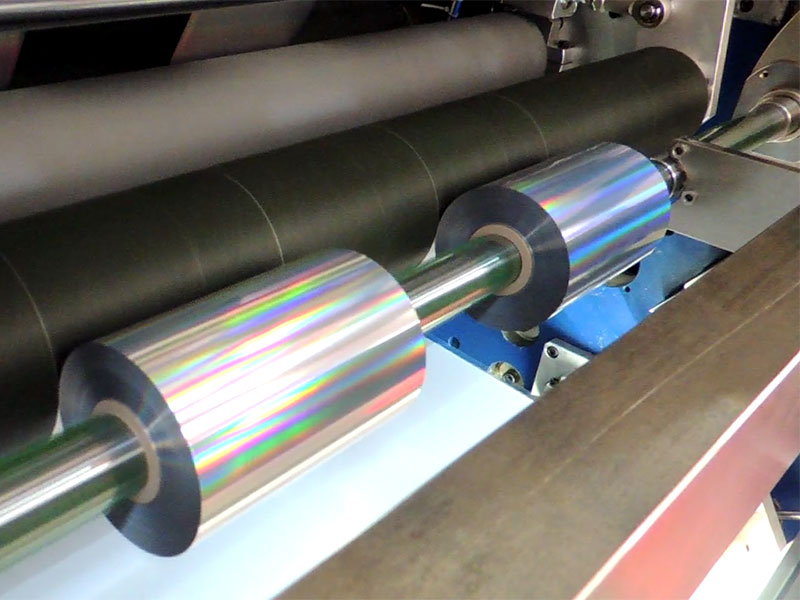

The working principle of the hot stamping foil slitting rewinder is relatively intuitive and efficient, and its core lies in the precise slitting and orderly rewinding of hot stamping foil coils. Here is a detailed explanation of the working principle of hot stamping foil slitting rewinder:

1. Coil positioning and feeding:

• The anodized aluminium coil is first placed on the coil positioning device, which ensures that the coil is fed stably and accurately into the subsequent processing process.

• By means of an uncoiling device or similar mechanical structure, the coil is progressively unwound and fed into the slitting unit.

2. Precise Slitting:

• The slitting device is one of the core components of the hot stamping foil slitter rewinder, which is responsible for slitting the coil according to the preset width or shape.

• Slitting devices are usually equipped with sharp blades or cutting tools, which are able to ensure the accuracy and efficiency of slitting under a precise control system.

• The slitting process can be either longitudinal or transverse, depending on the production needs.

3. Rewinding Processing:

• The slitted hot stamping foil coil is fed into a rewinding unit, which is responsible for rewinding the coil into smaller coils.

• Rewinding units are usually equipped with a rewinder and hold-down device to ensure that the coil remains tight and neat during the winding process.

• Precise control of the coil can be achieved by adjusting the parameters of the rewinding device, such as winding speed, winding tension, etc.

4. Repetitive Actions and Continuous Production:

• The entire workflow requires multiple repetitive movements to complete for efficient slitting and rewinding of hot stamping foil.

• Hot stamping foil slitter rewinders are usually equipped with an automated control system that enables precise control and monitoring of the entire production process.

5. Quality & Safety:

• Throughout the working process, the hot stamping foil slitting rewinder needs to ensure the quality and safety of the coil.

• This includes ensuring the accuracy of the slitting and avoiding wrinkles or breakage of the web during the winding process.

• At the same time, the equipment also needs to be equipped with the necessary safety protection devices to ensure the safety of operators.

To sum up, the working principle of the hot stamping foil slitting and rewinding machine is to achieve efficient, accurate and safe processing of hot stamping foil coils through the steps of coil positioning, precise slitting, rewinding processing, and repetitive action and continuous production.

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2 Manual Paper Core Cutter

Manual Paper Core Cutter