19. December, 2024delish0

Coding ribbon slitting machine is a kind of mechanical equipment specially used for slitting coding ribbon. The following is a detailed introduction to the coding ribbon slitting machine:

1. Definitions

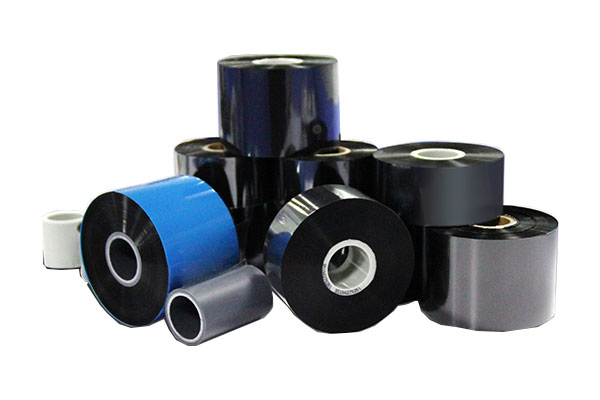

The coding ribbon slitting machine can accurately cut the ribbon material into the required width according to the needs of the printed matter specifications. It is widely used in the slitting and rewinding of thermal transfer ribbons, fax ribbons, barcode ribbons, coding ribbons and other materials.

2. The working principle

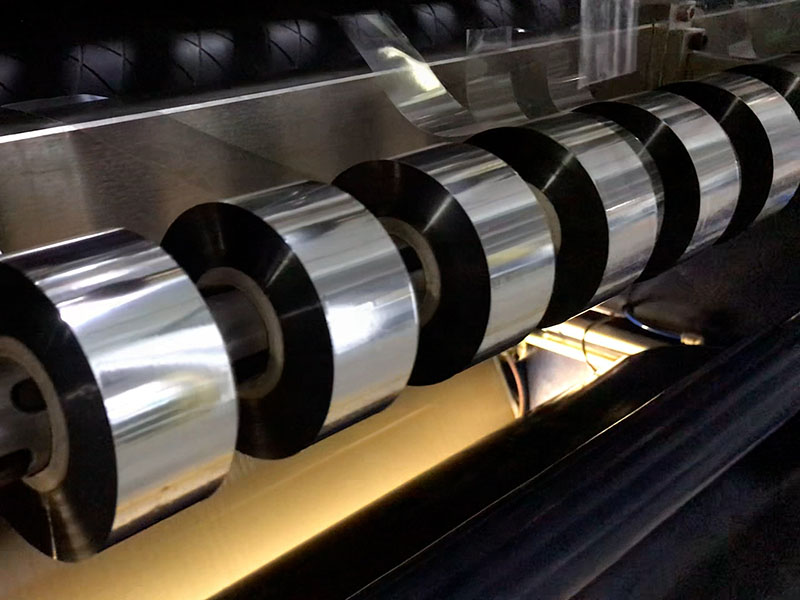

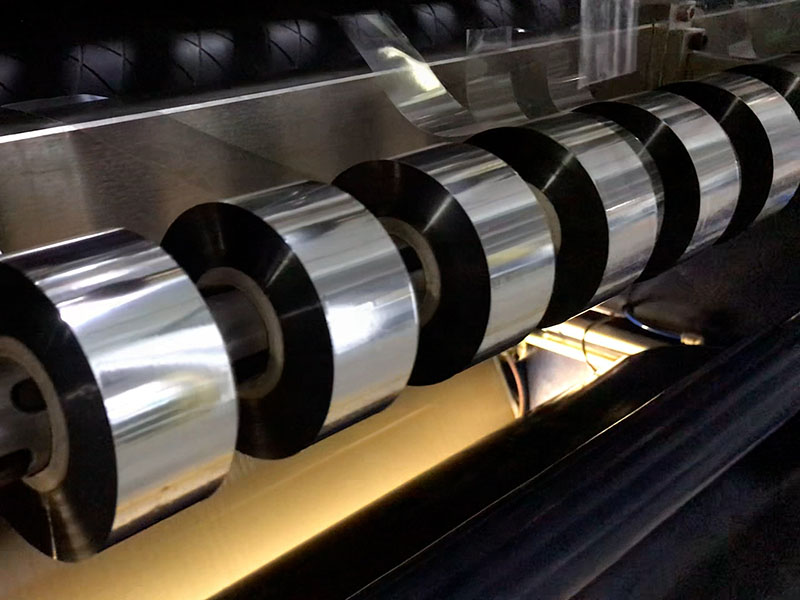

The working principle of the coding ribbon slitting machine is to drive the ribbon material forward through the mechanical transmission system, and the ribbon is slitted through the tool system. During the slitting process, the tension control system ensures that the ribbon material maintains a stable tension to ensure the slitting accuracy and the quality of the finished product. At the same time, the winding system is responsible for winding the slitted ribbon into a roll, which is convenient for subsequent storage and use.

3. Types and characteristics

1. Small ribbon slitting and rewinding machine:

• Typically slitted with a razor with a small slitting width and unwinding diameter.

• The slitting speed is relatively low, and the ribbon induction and film grafting process is usually in manual mode.

• Flexible, in addition to narrow slitting, long ribbons can be rewound into short rolls.

2. Automatic Heat Transfer Ribbon Slitting Machine:

• The effective slitting width is larger, and the unwinding diameter is also increased accordingly.

• Faster slitting speed, the ribbon can be semi-automatic or fully automatic.

• Equipped with high-precision adaptive tension control system to ensure stable tension during the slitting process.

• The overall modular design, easy to install and maintain, is suitable for high-efficiency batch ribbon slitting applications.

4. The field of application

Coding ribbon slitting machine is widely used in various occasions that require ribbon slitting, such as label printing, packaging printing, barcode printing and other fields. It increases productivity, maintains print quality, and reduces production costs.

5. Precautions

1. When operating the coding ribbon slitting machine, the safety operation procedures should be strictly adhered to to ensure personal safety.

2. Regularly maintain the equipment, check the wear and tear of the tools, and replace the seriously worn tools in time.

3. Clean the dust and dirt inside the equipment to keep the equipment clean and hygienic.

4. Adjust the slitting parameters according to the actual needs to ensure the stable quality of slitting.

To sum up, the coding ribbon slitting machine is an efficient and accurate mechanical equipment, which can meet various ribbon slitting needs, improve production efficiency and ensure product quality.

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2 Manual Paper Core Cutter

Manual Paper Core Cutter