What to pay attention to when using a paper tube cutter

When using a paper tube cutter, you need to pay attention to the following aspects to ensure the safety, efficiency and quality of the paper core:

1. Preparation before operation

1. Familiar with the equipment: Before operation, you should carefully read the instruction manual of the paper tube cutter, and be familiar with the structure, performance, operating procedures and safety precautions of the equipment.

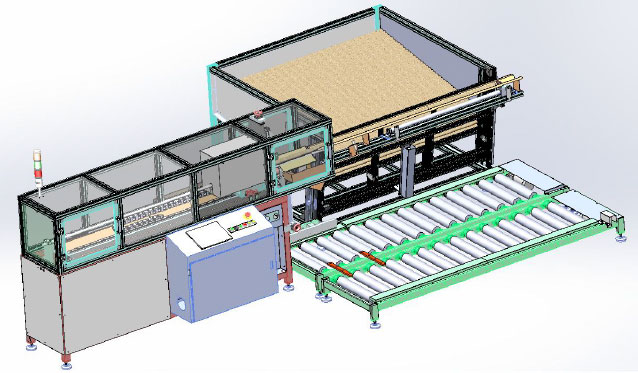

2. Equipment inspection: Check whether all parts of the paper tube cutter are in good condition, including blades, pressure wheels, conveyor belts, etc., to ensure that there is no loosening or damage. At the same time, check whether the power cord and electrical components are in good condition and whether the grounding is reliable.

3. Adjust the parameters: according to the specifications and requirements of the paper tube, adjust the relevant parameters of the paper tube cutting machine, such as cutting length, cutting speed, etc.

2. Precautions during operation

1. Wear protective equipment: When operating the paper cutter, you should wear labor protection equipment, such as protective glasses, gloves, work clothes, etc., to prevent flying debris or dust from harming your eyes and skin.

2. Place the paper core: Place the paper core on the conveyor belt of the paper core cutter, and make sure that the paper core is in the correct position to avoid offset or stagnation during the cutting process.

3. Start the device: After confirming that all parts of the device are normal, turn on the power first, and then start the paper tube cutter. During the cutting process, it is necessary to closely observe the operation of the equipment, and find and deal with abnormal situations in time.

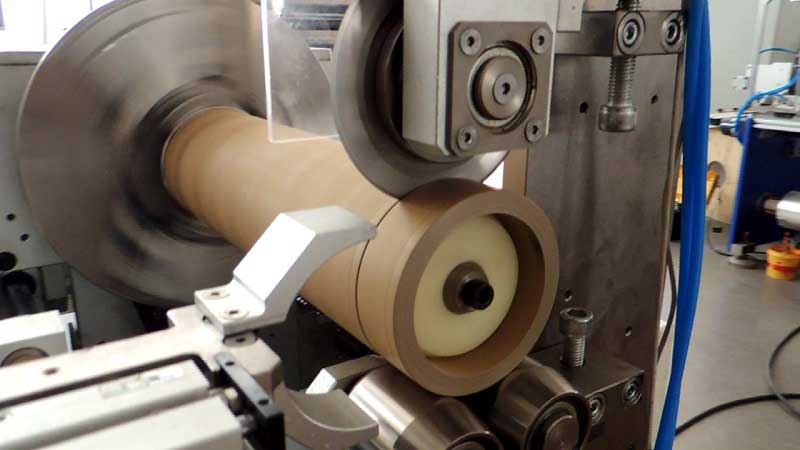

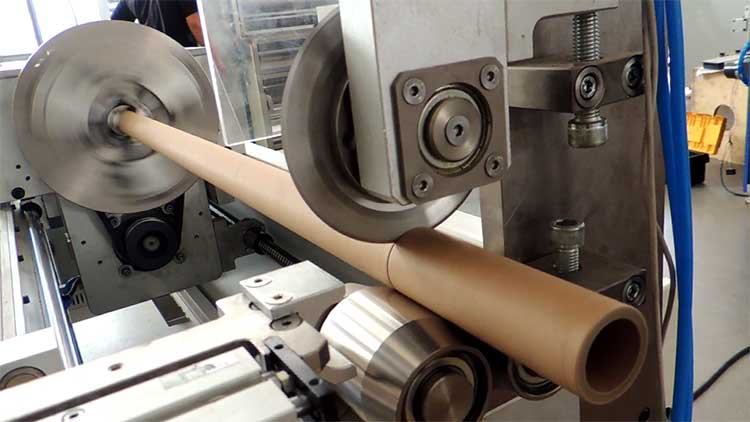

4. Cutting operation: During the cutting process, it is necessary to ensure that the cutting tool is in contact with the paper core evenly, so as to avoid cutting too deep or too shallow, resulting in damage or inaccurate size of the paper core. At the same time, it is necessary to pay attention to the control of cutting speed to avoid affecting the cutting quality too fast or too slow.

5. Emergency shutdown: In case of emergency or equipment failure, the emergency shutdown button should be pressed immediately and the power supply should be cut off. Restart the device only after troubleshooting.

3. Maintenance after operation

1. Clean up the equipment: After the cutting is completed, the paper scraps, dust and other debris on the paper cutting tube machine should be cleaned up in time to keep the equipment clean and tidy.

2. Check the cutting tool: check the wear of the cutting tool, if there is wear, it should be replaced or ground in time to ensure the cutting quality.

3. Lubricate the equipment: Lubricate the transmission parts of the paper tube cutter regularly to reduce friction and wear and prolong the service life of the equipment.

4. Storage equipment: When the paper tube cutter is not in use, it should be stored in a dry and ventilated place to avoid moisture or corrosion.

4. Safety precautions

1. Do not touch: During the operation of the paper tube cutter, it is strictly forbidden to touch the moving parts such as cutting knives and conveyor belts to avoid danger.

2. Prohibit non-professional operation: The paper tube cutter should be operated by professionally trained personnel to avoid equipment damage or casualties caused by non-professional misoperation.

3. Regular maintenance: Regularly maintain the paper tube cutter to ensure that the performance of the equipment is stable, safe and reliable.

To sum up, when using the paper tube cutter, it is necessary to pay attention to the preparation before operation, precautions during operation, maintenance and safety precautions after operation, etc. By strictly following these precautions and operating procedures, you can ensure safe operation, improve production efficiency, and improve the quality of paper cores.

Recent Post

Customized paper cutting tube machine: to meet the special needs of different industries26. April, 2025

Customized paper cutting tube machine: to meet the special needs of different industries26. April, 2025 Versatile application of slitting machines: precision cutting of film, paper, metal25. April, 2025

Versatile application of slitting machines: precision cutting of film, paper, metal25. April, 2025 How does the automatic paper tube cutter improve production efficiency?23. April, 2025

How does the automatic paper tube cutter improve production efficiency?23. April, 2025 Efficient and precise! Analysis of the core functions of the paper tube cutter22. April, 2025

Efficient and precise! Analysis of the core functions of the paper tube cutter22. April, 2025

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Paper Core Loading Machine

Paper Core Loading Machine Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2