What do you need to pay attention to when cutting paper tubes

The paper tube cutter needs to pay attention to the following aspects when cutting paper tubes to ensure operation safety, improve cutting accuracy and production efficiency:

1. Preparation and inspection before operation

1. Professional training: The operator should be professionally trained and familiar with the structure, performance, operating procedures and safety precautions of the paper tube cutting machine.

2. Equipment inspection: Before operation, carefully check whether all parts of the equipment are in good condition, especially key components such as cutters, iron presses, and positioning devices. At the same time, check whether the electrical equipment is well grounded, whether the electrical wiring is insulated, and whether the switch is normal and reliable.

3. Material preparation: According to the cutting requirements, prepare the paper tube of appropriate size and material, and ensure that the paper tube is stacked neatly and steadily.

2. Precautions in the cutting process

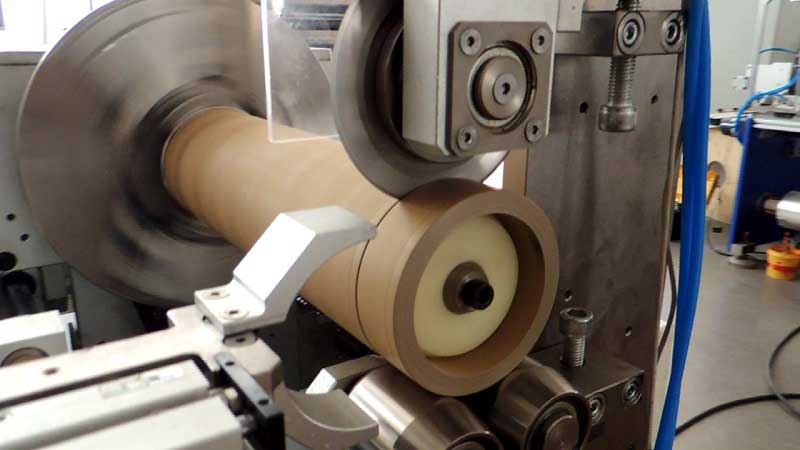

1. Accurate positioning: Use a positioning press to fix the paper core on the machine tool to ensure that the position of the paper core is accurate. At the same time, adjust the position and angle of the tool according to the cutting size requirements.

2. Cutting height: If you use a ventilated machine tool to cut paper, the height of the paper core should not exceed the maximum height specified by the machine tool (such as 125mm) to avoid overload operation of the machine or inaccurate cutting.

3. Cutting speed: According to the material and thickness of the paper core, select the appropriate cutting speed. Cutting too fast can lead to inaccurate cutting or tool damage, while cutting too slow can affect productivity.

4. Observation and adjustment: During the cutting process, the operator should closely observe the operation of the equipment, and find and deal with abnormal situations in time. For example, problems such as tool wear, paper core offset, etc., need to be adjusted in time.

5. No touching: During the cutting process, it is strictly forbidden to put your hand or other objects into the knife to avoid injury. At the same time, avoid placing other debris near the machine to avoid hindering operation or causing accidents.

3. Treatment and maintenance after cutting

1. Clean up the waste: After the cutting is completed, clean up the waste and chips in time to keep the working area tidy.

2. Check the cutting quality: Inspect the cut paper tube to ensure that the cutting size is accurate, the surface is flat, and there are no defects such as cracks.

3. Equipment maintenance: Regularly clean, lubricate and maintain the equipment to ensure stable performance and prolong the service life of the equipment.

4. Safety precautions

1. Wear protective equipment: Operators should wear labor protection equipment, such as protective glasses, gloves (whether to wear according to the actual situation), work clothes, etc.

2. Comply with operating procedures: Operators should strictly abide by operating procedures and safety precautions, and shall not adjust equipment parameters or carry out dangerous operations without authorization.

3. Emergency shutdown: In case of emergency or equipment failure, the machine should be stopped immediately and the maintenance personnel should be notified for treatment.

To sum up, the paper tube cutter needs to pay attention to the preparation and inspection before operation, the precautions in the cutting process, the treatment and maintenance after cutting, and the safety precautions when cutting the paper tube. By strictly following these precautions and operating procedures, you can ensure operational safety, improve cutting accuracy, and improve productivity.

Recent Post

Customized paper cutting tube machine: to meet the special needs of different industries26. April, 2025

Customized paper cutting tube machine: to meet the special needs of different industries26. April, 2025 How does the high-precision cutting function of the slitter help improve product quality?25. April, 2025

How does the high-precision cutting function of the slitter help improve product quality?25. April, 2025 Versatile application of slitting machines: precision cutting of film, paper, metal25. April, 2025

Versatile application of slitting machines: precision cutting of film, paper, metal25. April, 2025 How does the automatic paper tube cutter improve production efficiency?23. April, 2025

How does the automatic paper tube cutter improve production efficiency?23. April, 2025

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Paper Core Loading Machine

Paper Core Loading Machine Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2