Introduce the advantages of the thermal transfer ribbon slitting machine

Thermal transfer ribbon slitting machine has significant advantages in the thermal transfer industry, which are mainly reflected in the following aspects:

1. High-precision slitting

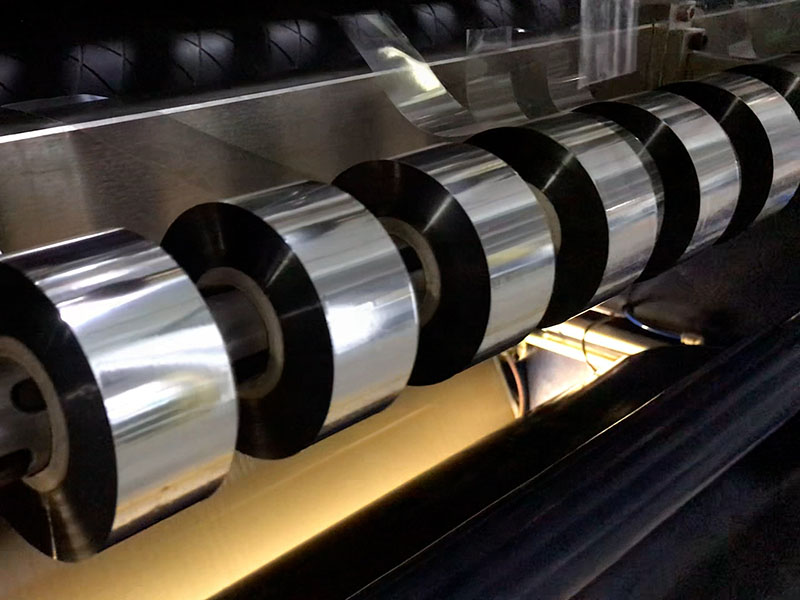

• Accurate size: The thermal transfer ribbon slitting machine can accurately cut the ribbon material into the required width according to the needs of the printed product specifications. This high-precision slitting ensures the stability and reliability of the ribbon in subsequent use.

• Stable quality: The slitting machine will precisely control the cutting speed and cutting accuracy during the slitting process, so as to ensure the stable quality of the slitted ribbon.

2. Efficient automation

• Fast slitting: The thermal transfer ribbon slitting machine adopts automatic control, which can quickly and accurately complete the slitting task and improve production efficiency.

• Material saving: Some thermal transfer ribbon slitting machines also have material-saving functions, such as automatic edge alignment, automatic deviation correction, etc., which can minimize material waste.

• Reduce labor costs: The highly automated slitting machine can realize the functions of automatic feeding, automatic cutting and automatic receiving, reducing manual intervention and errors, and reducing labor costs.

3. Widely used

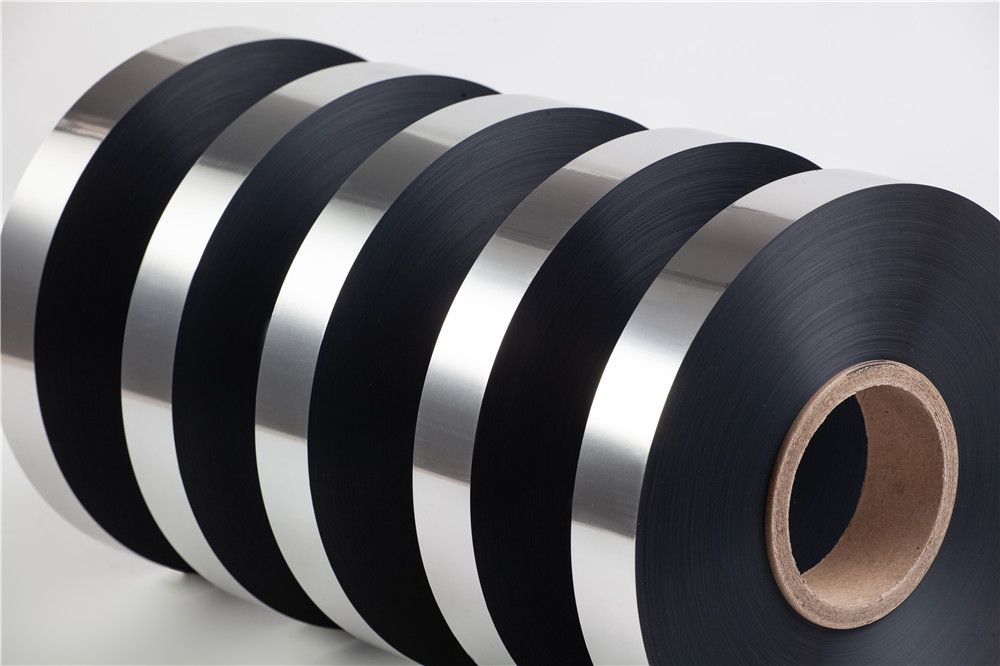

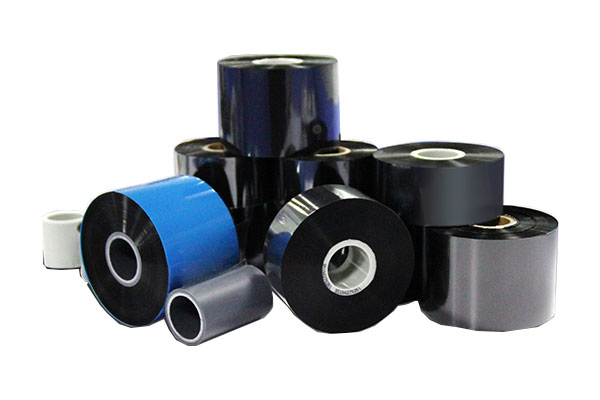

• Multi-material processing: The thermal transfer ribbon slitting machine is able to handle a variety of ribbon materials, including wax-based, resin-based and mixed-based, to meet different printing needs.

• Cross-industry applications: In addition to the heat transfer industry, heat transfer ribbon slitting machines are also widely used in many industries such as packaging, printing, leather processing, and electronic product assembly. Its efficient, precise and automated characteristics enable these industries to complete material slitting tasks more efficiently and accurately in the production process.

Fourth, advanced control system

• High-precision control system: The thermal transfer ribbon slitting machine usually adopts PLC control or touch screen control, which has the characteristics of high precision, high stability and easy operation. These control systems are able to monitor the operating status of the slitter in real time and adjust the slitting parameters as needed.

• Tension control: The slitting machine is equipped with a high-precision tension control system, which can ensure that the material maintains a stable tension during the slitting process. This avoids the problem of stretching, deformation or damage to the material, guaranteeing the printing result of the final product.

5. Flexibility and versatility

• Flexible adjustment: The thermal transfer ribbon slitting machine has strong versatility and flexibility, which can be subdivided according to the specifications and types of different ribbons, and adjust and optimize the process parameters according to the quality of the finished film coil.

• Versatility: In addition to the slitting function, some thermal transfer ribbon slitters also have a rewinding function, which can rewind long ribbons into short rolls or convert cores of different sizes.

To sum up, the heat transfer ribbon slitting machine plays an important role in the heat transfer industry with its advantages of high-precision slitting, efficient automation, wide application, advanced control system, and flexibility and versatility. These advantages make the thermal transfer ribbon slitting machine one of the indispensable equipment in the thermal transfer industry.

Recent Post

Customized slitting solutions: How can ribbon slitting machines meet the needs of different industries?15. April, 2025

Customized slitting solutions: How can ribbon slitting machines meet the needs of different industries?15. April, 2025 How does the ribbon slitting machine achieve micron slitting? Key technologies are all revealed14. April, 2025

How does the ribbon slitting machine achieve micron slitting? Key technologies are all revealed14. April, 2025 Ribbon slitting machine purchase guide: how to choose the slitting width and accuracy according to the demand?28. March, 2025

Ribbon slitting machine purchase guide: how to choose the slitting width and accuracy according to the demand?28. March, 2025 How much is the appropriate slitting speed of the label ribbon slitting machine03. January, 2025

How much is the appropriate slitting speed of the label ribbon slitting machine03. January, 2025

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Paper Core Loading Machine

Paper Core Loading Machine Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2