What materials is the thermal transfer ribbon slitting machine suitable for

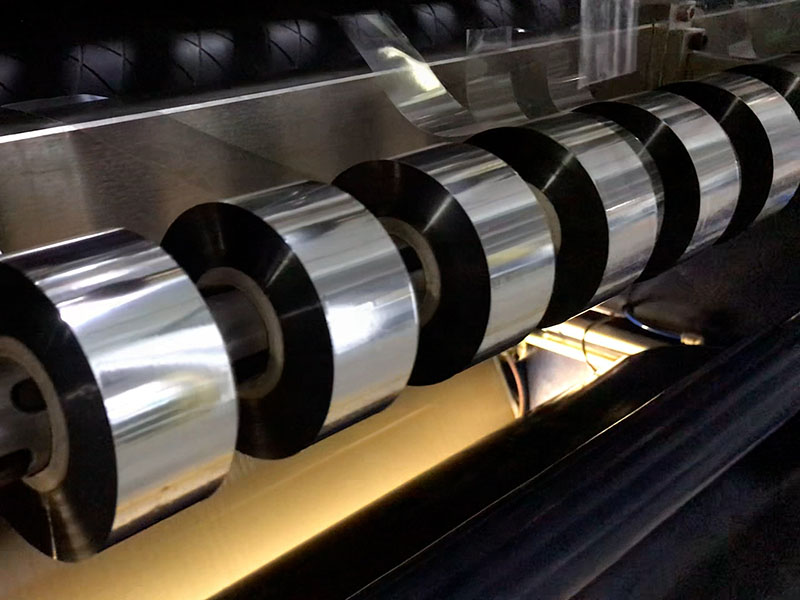

The thermal transfer ribbon slitting machine is mainly suitable for processing the ribbon material used in the thermal transfer technology. These materials often have specific heat-sensitive coatings that react with inks or pigments on substrates (e.g., paper, cloth, plastic, etc.) when heated to enable image transfer. Here are some common materials suitable for thermal transfer ribbon slitting machines:

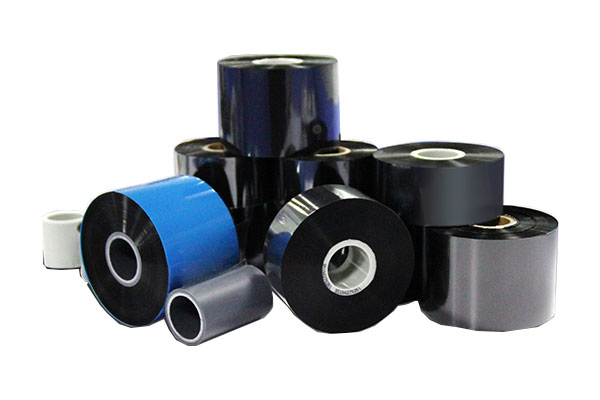

1. Thermal Transfer Ribbon: This is the most direct application material, including wax base, resin base and mixed base and other types. These ribbons are typically coated with a heat-sensitive coating that releases ink or pigment when heated.

2. Thermal Paper: Although thermal paper itself is not a ribbon, it is used as a substrate in some thermal transfer applications to print through a thermal transfer machine along with the ribbon. Thermal transfer ribbon slitting machines can also be used to slice this particular type of paper.

3. Thermal Transfer Film: This is a special thin film material, usually with a heat-sensitive coating. When heated, the ink or pigment on the film is transferred to the substrate. Thermal transfer ribbon slitting machines can be used to slit thermal transfer film into the desired width.

4. Ribbons: Ribbons are used as ribbons in some thermal transfer applications, especially in barcode printing and label printing. The toner on the ribbon is transferred to the substrate when heated, creating a clear image or text. The thermal transfer ribbon slitting machine is also suitable for slitting this ribbon material.

5. Other special materials: In addition to the above common materials, there are also some special materials that can also be used in thermal transfer technology, such as special cloth, leather, metal sheets, etc. These materials may require special slitter setups or knives when slitting, but thermal transfer ribbon slitters often have some versatility and flexibility to accommodate the needs of these special materials.

It should be noted that different thermal transfer ribbon slitting machines may have different scope of application and performance characteristics. When choosing a slitting machine, it is necessary to consider the specific material type, slitting requirements, production efficiency and other factors. At the same time, it is also necessary to ensure that the slitting machine has good stability and durability to ensure long-term stable slitting quality and production efficiency.

Recent Post

Customized slitting solutions: How can ribbon slitting machines meet the needs of different industries?15. April, 2025

Customized slitting solutions: How can ribbon slitting machines meet the needs of different industries?15. April, 2025 How does the ribbon slitting machine achieve micron slitting? Key technologies are all revealed14. April, 2025

How does the ribbon slitting machine achieve micron slitting? Key technologies are all revealed14. April, 2025 Ribbon slitting machine purchase guide: how to choose the slitting width and accuracy according to the demand?28. March, 2025

Ribbon slitting machine purchase guide: how to choose the slitting width and accuracy according to the demand?28. March, 2025 How much is the appropriate slitting speed of the label ribbon slitting machine03. January, 2025

How much is the appropriate slitting speed of the label ribbon slitting machine03. January, 2025

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Paper Core Loading Machine

Paper Core Loading Machine Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2