What material types of ribbon slitting machine is suitable for

Ribbon slitting machines are widely used in ribbon slitting of various material types, mainly including the following:

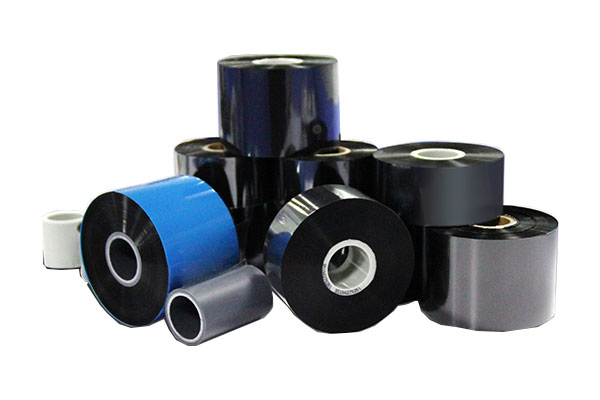

1. Thermal transfer ribbon

Thermal transfer ribbon is one of the main application objects of ribbon slitting machine. This kind of ribbon is usually composed of an ink layer, a heat-resistant layer and a base film, which can be divided into three types: wax base, resin base and mixed base according to the content of ink coating materials. Thermal transfer ribbons melt and transfer ink to the substrate through the thermal transfer head during the printing process, forming text and images. The ribbon slitting machine can cut the thermal transfer ribbon and other materials into the required width according to the needs of the printed matter specifications.

Second, fax ribbon and barcode ribbon

Fax ribbons and barcode ribbons are also common applications for ribbon slitting machines. These ribbons are commonly used in fax machines and barcode printers to transmit and print text or barcode information. The ribbon slitting machine can accurately slitting according to the specifications and requirements of these ribbons to meet the needs of different equipment.

3. Coded ribbon

The coding ribbon is mainly used to print logos, numbers and other information on various items. The ribbon slitting machine can also accurately slitting the coding ribbon to ensure the coding effect and printing quality.

Fourth, other types of ribbons

In addition to the above common ribbon types, ribbon slitting machines can also be applied to other types of ribbon slitting, such as ribbons, label ribbons, etc. These ribbons have a wide range of applications in different fields, such as ribbons are often used in barcode printing, label printing and other fields; Label ribbons are used to make various labels, such as product labels, logistics labels, etc.

Precautions

1. When using the ribbon slitting machine for slitting, it is necessary to select the appropriate equipment and parameters according to the requirements of the material, width, thickness and slitting accuracy of the ribbon.

2. During the slitting process, it is necessary to keep the equipment clean and tidy to avoid the influence of dust and debris on the slitting effect.

3. Operators need to have certain professional skills and knowledge, and be familiar with the performance and operation and maintenance methods of the equipment to ensure the normal operation of the equipment and the quality of the products.

To sum up, the ribbon slitting machine is suitable for ribbon slitting of various material types, including heat transfer ribbon, fax ribbon, barcode ribbon, coding ribbon and other types of ribbons. In practical applications, it is necessary to select the appropriate equipment and parameters for slitting according to specific needs and conditions.

Recent Post

How to choose the right ribbon slitting machine? These 5 features are key!07. April, 2025

How to choose the right ribbon slitting machine? These 5 features are key!07. April, 2025 Why do high-end ribbon slitting machines use servo motors? Stability increased by 80%!05. April, 2025

Why do high-end ribbon slitting machines use servo motors? Stability increased by 80%!05. April, 2025 Why is it said that high-quality ribbon slitting machine is more cost-effective?03. April, 2025

Why is it said that high-quality ribbon slitting machine is more cost-effective?03. April, 2025 Low ribbon slitting efficiency? Fully automatic high-speed slitting machine, production capacity increased by 50%!02. April, 2025

Low ribbon slitting efficiency? Fully automatic high-speed slitting machine, production capacity increased by 50%!02. April, 2025

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Paper Core Loading Machine

Paper Core Loading Machine Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2