What is the difference between aluminum foil slitting machine and copper foil slitting machine

There are some significant differences in design and functionality between aluminum foil slitter and copper foil slitter, which are mainly due to the different characteristics of the materials they handle and the processing requirements. Here's a detailed comparison of the two:

First, material characteristics and processing requirements

1. Aluminum foil

• Characteristics: Aluminum foil has the characteristics of light weight, corrosion resistance, easy processing and excellent barrier properties.

• Handling requirements: High cutting speed is usually required, and there are also certain requirements for cutting accuracy and surface quality to avoid scratches and scrap.

2. Copper foil

• Characteristics: Copper foil has good electrical and thermal conductivity, as well as high mechanical strength and chemical stability.

• Processing requirements: Since copper foil is commonly used in electronics, electrical, and communication fields, there are high requirements for its cutting accuracy and edge quality to ensure the stability and reliability of the circuit.

Second, the difference between machine design and function

1. Cutting speed and precision

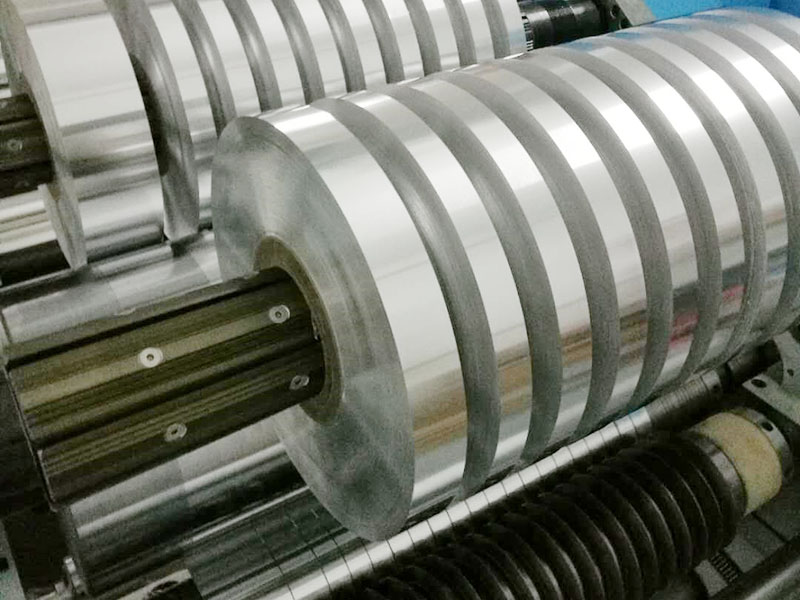

• Aluminum foil slitting machine: It is usually designed with a high cutting speed to meet the needs of efficient processing of aluminum foil materials. At the same time, it also has a certain cutting accuracy, but it may not be as fine as the copper foil slitting machine.

• Copper foil slitting machine: pay more attention to cutting precision and stability to ensure the cutting quality of copper foil. Although the cutting speed may be slightly slower, it can meet the requirements of high-precision machining.

2. Knives and cutting methods

• Aluminum foil slitting machine: Thicker cutting blades are usually used to adapt to the cutting characteristics of the aluminum foil material. At the same time, it may be equipped with a variety of tools to cope with different thicknesses and specifications of aluminum foil materials.

• Copper foil slitting machine: A finer cutting blade is required to ensure that the cutting edge of the copper foil is flat and burr-free. In addition, the copper foil slitting machine may also be equipped with more advanced cutting systems, such as laser cutting or precision mechanical cutting.

3. Degree of automation and control system

• Aluminum foil slitting machine: usually has a high degree of automation, capable of automatic feeding, cutting and winding, reducing manual intervention. At the same time, it is equipped with an advanced control system to achieve precise cutting and winding control.

• Copper foil slitting machine: It also has a high degree of automation and control accuracy, but may pay more attention to real-time monitoring and adjustment of the cutting process to ensure the cutting quality of copper foil.

Third, applicable fields and market demand

1. Aluminum foil slitting machine:

• Widely used in food packaging, building insulation, battery separator and other fields. With the rapid development of these industries, the demand for aluminum foil slitting machines is also increasing.

2. Copper foil slitting machine:

• Mainly used in electronics, electrical and communication fields, such as the manufacture of cross-linked cables, grounding wires, flexible circuit boards, etc. These fields have high requirements for the cutting quality and precision of copper foil, so the market demand for copper foil slitting machines is also relatively stable.

To sum up, there are significant differences between aluminum foil slitting machine and copper foil slitting machine in terms of material characteristics and processing requirements, machine design and function differences, and applicable fields and market demand. Therefore, when selecting and using, it needs to be comprehensively considered according to the specific processing needs and material characteristics.

Recent Post

Analysis of the core technology of hot stamping paper slitting machine: precise slitting and efficiency improvement26. March, 2025

Analysis of the core technology of hot stamping paper slitting machine: precise slitting and efficiency improvement26. March, 2025 Efficient and accurate: the core advantages and application fields of aluminum foil slitting machine20. February, 2025

Efficient and accurate: the core advantages and application fields of aluminum foil slitting machine20. February, 2025 The application of hot stamping film slitting machine in the anodized aluminum hot stamping process04. January, 2025

The application of hot stamping film slitting machine in the anodized aluminum hot stamping process04. January, 2025 The application advantages of hot stamping film slitting machine in the anodized aluminum hot stamping process04. January, 2025

The application advantages of hot stamping film slitting machine in the anodized aluminum hot stamping process04. January, 2025

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Paper Core Loading Machine

Paper Core Loading Machine Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2