Lithium battery pole piece slitting technology and application

Lithium battery electrode piece slitting is an important part of the lithium battery production process, which involves the coated positive and negative electrode pieces are accurately cut according to the design requirements to meet the needs of battery assembly. The following is a detailed introduction to the slitting technology of lithium battery pole piece:

1. Technical overview

The lithium battery pole piece slitting technology mainly uses high-precision mechanical equipment and tools to slitting the coated pole piece. This process requires extreme precision and stability to ensure that the cut pole pieces are consistent in size, with flat edges and free of burrs, thus guaranteeing the performance and safety of the battery.

2. The slitting method

There are several ways to divide lithium battery pole pieces:

• Disc slitting: Rotary cutting of pole pieces with disc cutters, which is relatively inexpensive, but may be slightly inferior in cutting accuracy and edge quality to other methods.

• Mold stamping: Stamping and cutting the pole piece through the mold, which is suitable for mass production, but the production and maintenance cost of the mold is high.

• Laser cutting: The laser beam is used to cut the pole piece non-contact, which has the advantages of high precision, no burr and no stress, but the equipment cost is high, and the heat-affected area may be generated during the cutting process.

3. Slitting equipment

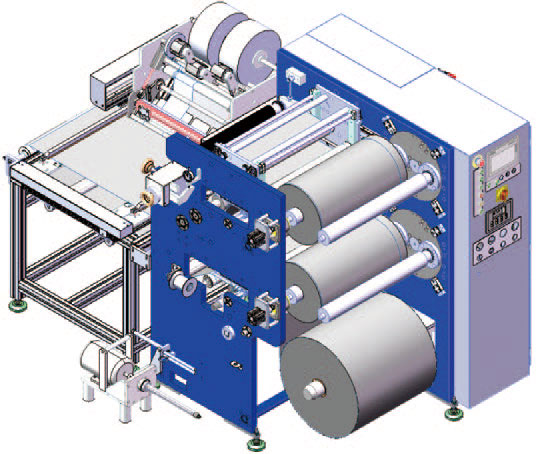

The lithium battery pole piece slitting machine is the key equipment to accomplish this task. It is usually composed of parts such as feeding system, cutting system, receiving system and control system. The cutting system uses a sharp knife or laser beam to cut the pole piece, while the control system is responsible for precisely controlling the cutting size and speed to ensure cutting accuracy and stability.

4. Technical characteristics

• High precision: Lithium battery pole piece slitting requires extremely high cutting accuracy to ensure the dimensional consistency of the pole piece and the smooth progress of battery assembly.

• High efficiency: high degree of automation, can quickly complete the slitting of a large number of pole pieces, and improve production efficiency.

• Good stability: The equipment is manufactured with high-quality materials and stable process to ensure stable performance and accuracy in long-term operation.

5. The field of application

Lithium battery electrode slitting technology is widely used in the lithium battery manufacturing industry and is an important link in the battery production line. With the rapid development of electric vehicles, energy storage systems, mobile communications and other fields, the demand for lithium batteries is increasing, and the slitting technology of lithium battery pole pieces is also facing higher requirements and challenges.

6. Future trends

With the continuous progress of science and technology and the continuous development of the industry, the lithium battery pole piece slitting technology will show the following trends:

• Intelligent: Through the introduction of advanced control technology and sensor technology, the intelligent control and remote monitoring of the equipment are realized.

• Automation: Further improve the degree of automation of equipment, reduce manual intervention, and improve production efficiency and product quality.

• Environmental protection: The use of more environmentally friendly cutting technology and materials to reduce pollution and emissions in the production process, in line with the requirements of sustainable development.

To sum up, lithium battery electrode slitting technology plays a vital role in lithium battery manufacturing. With the continuous development of the industry and the continuous progress of technology, this technology will continue to be upgraded and improved to provide strong support for the development of the lithium battery industry.

Recent Post

Copper foil slitting machine for lithium battery: help the development of new energy industry19. March, 2025

Copper foil slitting machine for lithium battery: help the development of new energy industry19. March, 2025 High-precision copper foil slitting machine: escort your lithium battery production12. March, 2025

High-precision copper foil slitting machine: escort your lithium battery production12. March, 2025 The application of slitting machine in the processing of new energy materials12. February, 2025

The application of slitting machine in the processing of new energy materials12. February, 2025 The pole piece slitting machine is a key equipment on the lithium battery production line20. November, 2024

The pole piece slitting machine is a key equipment on the lithium battery production line20. November, 2024

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Paper Core Loading Machine

Paper Core Loading Machine Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2