19. October, 2024delish0

First, preparation before starting

1. Inspect the working conditions of the equipment. Make sure that the device is free of fouling and that there is no debris around the device.

2. Check the electricity and gas supply of the equipment. Ensure that the supply of electricity and gas is normal,

3. Pick up the paper tube for cutting.

Second, the operation method

1. Power on: The machine is turned on with compressed air, the person stands facing the operation panel, turns on the main power supply, turns on the power switch of the equipment, and presses the start button, at this time the number displayed on the operation panel represents the position of the cutter.

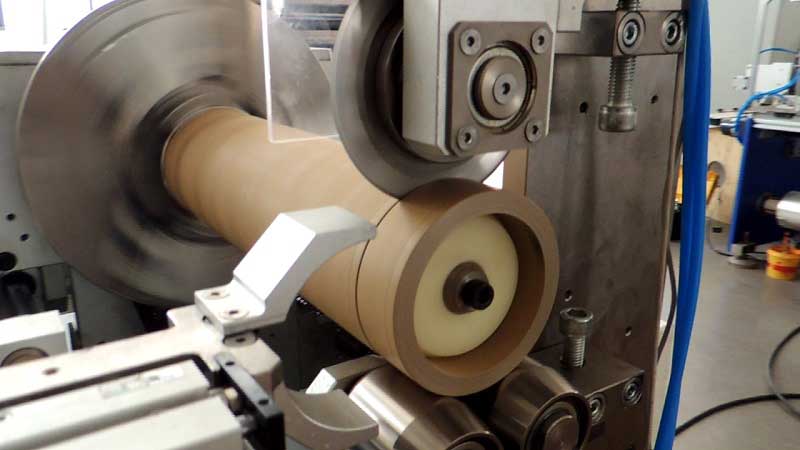

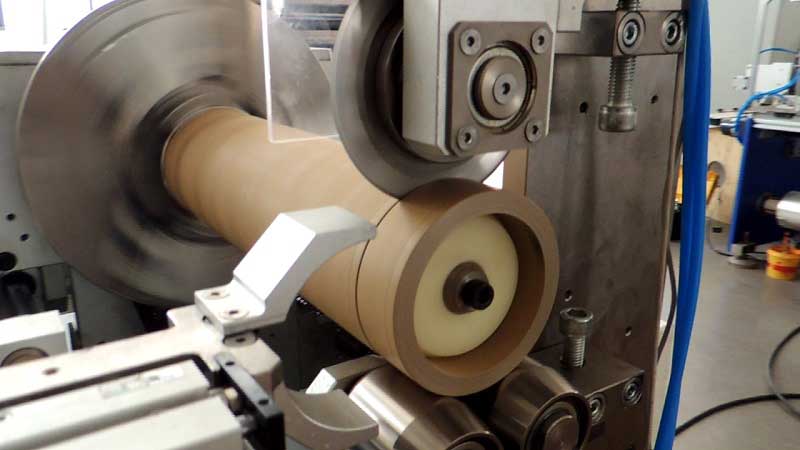

2. Loading paper tube: twist the cylinder valve handle at the right end of the machine body downward, at this time, the paper tube chuck at the left end of the rotating shaft is opened, and the fixture at the right end of the rotating shaft is opened, and the paper tube is penetrated from the right end of the rotating shaft to the leftmost end, and the cylinder valve handle is lifted upwards to clamp the paper tube and fix the rotating shaft.

3. Cutting: Turn the cutter platform handwheel, adjust the cutter to the position of about 15 mm to the left of the right end face of the paper core, press the "start" button, rotate the rotating shaft, press the "inlet" button, the cutter is close to the paper core for cutting, when the paper core is cut off, press the "retract" button immediately, press the "reset" button to clear the position on the operation panel. Move the cutter platform to the left so that the indication on the operation panel is the same as the length of the paper core to be cut, the feed cut, the retract knife is cleared, and at this time, the production of a target paper core is completed. Move the cutter platform to the left to continue making the next paper tube.

4. Paper unloading tube: When the paper tube on the rotating shaft is cut, press the "Stop" button, twist the cylinder valve handle downward, remove the paper tube, and place it in a classified manner. 5. Continuous production: Repeat the above steps 2, 3, and 4 to carry out continuous production, 6. Shutdown: Turn off the power switch, turn off the main power, and clean the paper scraps on the cutter and the fuselage.

Third, precautions

1. This equipment is operated by a special person, and other personnel are prohibited from operating this equipment without authorization.

2. When the equipment is running, it is forbidden to touch any moving and rotating parts.

3. When operating the equipment, if problems are found, report them in time, and it is strictly forbidden to disassemble the equipment without permission

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2 Manual Paper Core Cutter

Manual Paper Core Cutter