Several common roll problems and treatment methods of rewinding machine

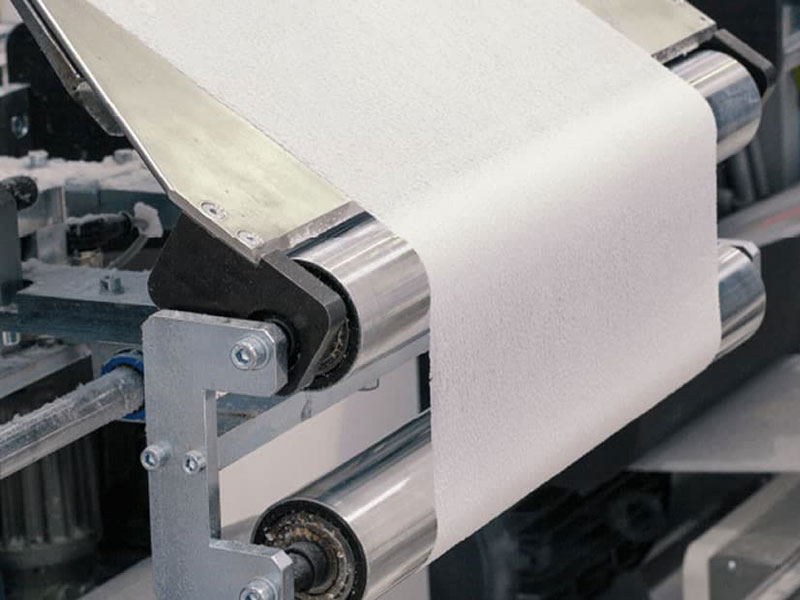

The rewinder is generally used for the rewinding and slitting of mica tape, paper and film, and there are several common problems in the process of use.

1. The weight of each roll of the paper rod rolled out by the rewinder is different, and the number of laps on the computer is set, but the weight always runs.

Solution: There are three main reasons why the weight of the paper rolled out by the rewinder is different, one is that the width of each roll you cut is different, the second is that the quantitative width of the base paper has changed, and the third is that you do not have a stretch roller, and the paper is wrinkled in the part and thus the weight becomes larger.

2. How to make full use of paper and reduce waste?

How to deal with this: This requires you to pay more attention to it in normal times; First of all, you have to work procurement, and the width of the large paper roll you buy should be appropriate, so that there are fewer two sides to cut. Secondly, when you rewind, try not to break the paper and do not present non-conforming products, so as to reduce waste.

3. The roll paper cut by the paper cutter is always crooked, how to adjust the flat point.

Solution: The paper roll cut out by the paper cutter is always crooked, and this must fix the parallelism between your large paper roll and the cylinder of the rewinder, otherwise the paper will be crooked. Also, the arc of your stretching roller should be adjusted well, otherwise there will be deviation.

4. When rolling the paper, it is always broken on the right side, and the result is always that it is not rolled and cannot be rolled.

Solution: If it is always broken on the right, then it is necessary to check whether the tension of this side of the paper is greater than that on the left, whether the extension roller or the large roll of paper is more behind this side, causing this side to be pulled too tightly and break the paper.

5. There is always a problem on a rainy day, is it related to the wet paper, what to do?

Treatment method: toilet paper has good water absorption, due to the large air humidity on rainy days, it is possible to show the dryness of the outer layer and the inner layer of the large roll, which provokes the deformation of the paper, and the strength also changes. To eliminate this problem, you need to think about the ventilation of the workshop and try to stick to the boring of the workshop.

Recent Post

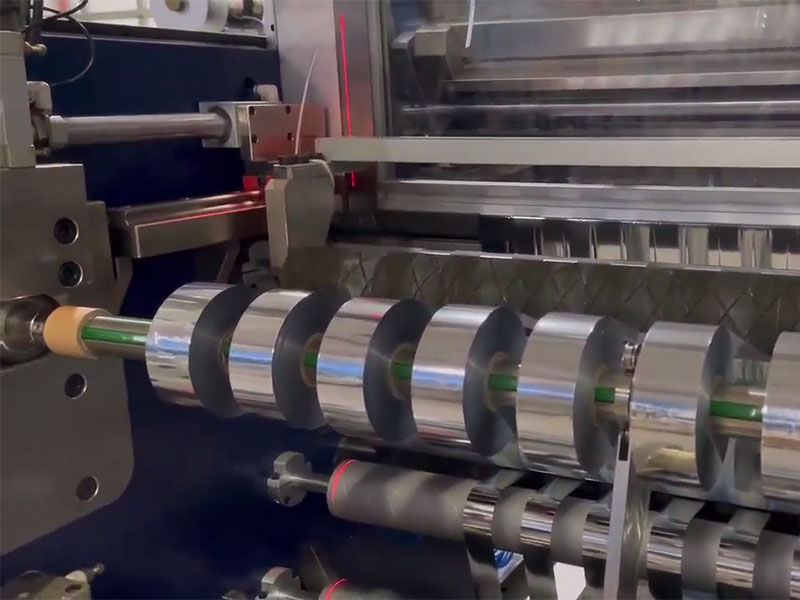

Slitting + rewinding machine: the ultimate solution to double the slitting efficiency of hot stamping foil!02. April, 2025

Slitting + rewinding machine: the ultimate solution to double the slitting efficiency of hot stamping foil!02. April, 2025 How to improve the working efficiency of slitting and rewinding machine?01. April, 2025

How to improve the working efficiency of slitting and rewinding machine?01. April, 2025 How to ensure the slitting accuracy of the slitting rewinder?28. March, 2025

How to ensure the slitting accuracy of the slitting rewinder?28. March, 2025 Efficient and accurate: the core advantages and application scenarios of ribbon slitting machine17. February, 2025

Efficient and accurate: the core advantages and application scenarios of ribbon slitting machine17. February, 2025

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Paper Core Loading Machine

Paper Core Loading Machine Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2