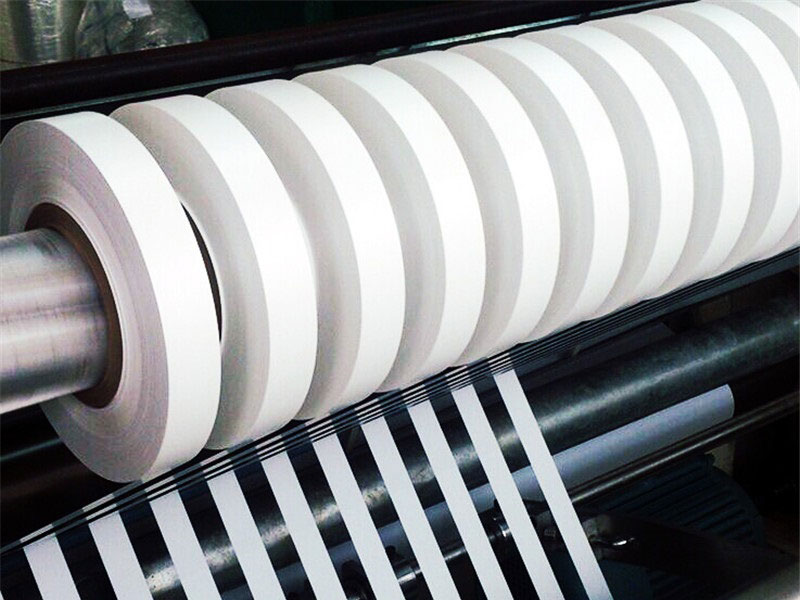

Causes and solutions for paper breaks in the rewinder

After the mechanical equipment is used for a period of time, it is inevitable that there will be one or another problem, and the same is true for the rewinder. We've probably all encountered a broken rewinder, but have you found a solution? Next, let's talk about the reasons and solutions for the paper break of the rewinder.

1. Check whether there is a problem with your base paper, if there is no problem with the base paper, check whether the tension is consistent when the rewinder starts.

2. Check whether there is burr in the rewinded toilet paper, and then check whether the guide roller and unwinder of the toilet paper rewinder are installed correctly.

3. See whether there is a break in the cutting round knife of the rewinder, whether the angle of the knife is adjusted correctly, and the whole paper must be adjusted before passing through the longitudinal cutting device - on the same horizontal line.

4. Check whether there are wrinkles on the base paper, if there is a paper break caused by the base paper, the base paper can be processed.

5. Check whether there are waves in the unrolled base paper, if there is a possibility that the moisture of the base paper is uneven.

6. Check the quantification of the base paper in the entire transverse direction of the toilet paper rewinder, the moisture is uneven, resulting in uneven longitudinal tension when unwinding, it is recommended to adjust the medium and high rollers.

If the above reasons and solutions can not solve your problem, please contact us in time, and the real cause of the problem can be found through your detailed description.

Recent Post

How to improve the working efficiency of slitting and rewinding machine?01. April, 2025

How to improve the working efficiency of slitting and rewinding machine?01. April, 2025 How to ensure the slitting accuracy of the slitting rewinder?28. March, 2025

How to ensure the slitting accuracy of the slitting rewinder?28. March, 2025 How about the production efficiency of the rewinder21. December, 2024

How about the production efficiency of the rewinder21. December, 2024 How to maintain the hot stamping foil slitting rewinder21. December, 2024

How to maintain the hot stamping foil slitting rewinder21. December, 2024

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Paper Core Loading Machine

Paper Core Loading Machine Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2