Analysis of common fault causes and solutions of rewinders

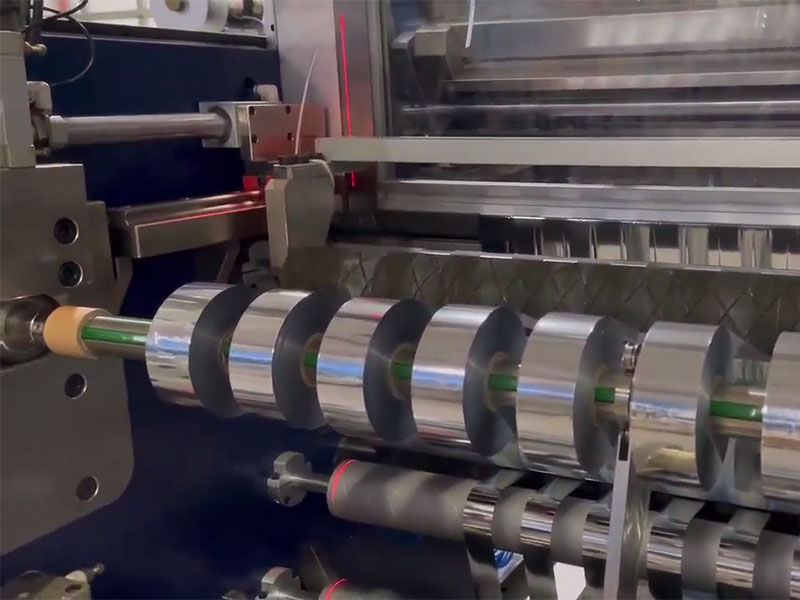

The rewinder is generally used for the rewinding and slitting of mica tape, paper and film, and plays the role of everything in two. Mechanical equipment will also fail in long-term use, so let's take a look at the common faults of the rewinder.

1. Common abnormalities of the rewinding machine, the length of the core tube is correct, after the core tube goes down to the front track, the trolley does not push the core tube to the corresponding position in the rear section, the core tube is backlogged in the front section, and the automatic tube stops. Abnormal cause: unknown (no abnormality in the instrument and control inspection), solution: this batch is manually put on the tube, the knife is changed online, the sorting order is changed, or the width is changed ± 1-2mm (the latter is usually selected, which is convenient for the core tube operator), and then reset, and the next batch is automatically put on the tube. Generally, you can change the knife online once, this class has tried to change the knife online at most 3 times in a row, and the last shift is used normally, and it is suspected that it may be a problem with the program.

2. The second common abnormality of the rewinder is correct, the core tube has reached the ready position, and the sensing limit also senses the core tube, but it does not start to automatically lower the tube. Solution: Reset, this batch of manual tubes, online tool change, when the tool is successfully manually put on the tube, check whether the limit near the position of the tube pushing trolley is disturbed by the broken paper, check OK, drive, accelerate and then reset, automatic, it should be OK.

3. The operator is too fast on the tube, and does not pay attention, in the case of a tube in the track, the reset and empty the data, and automatically the next batch of core tubes, resulting in the motor protection alarm of the tube pushing trolley. Don't worry, after the paper is unloaded, take out all the core tubes in the track, and manually hit the tube pushing trolley to the initial position on the inner touch screen, and the abnormality is lifted.

Recent Post

Slitting + rewinding machine: the ultimate solution to double the slitting efficiency of hot stamping foil!02. April, 2025

Slitting + rewinding machine: the ultimate solution to double the slitting efficiency of hot stamping foil!02. April, 2025 How to improve the working efficiency of slitting and rewinding machine?01. April, 2025

How to improve the working efficiency of slitting and rewinding machine?01. April, 2025 How to ensure the slitting accuracy of the slitting rewinder?28. March, 2025

How to ensure the slitting accuracy of the slitting rewinder?28. March, 2025 Efficient and accurate: the core advantages and application scenarios of ribbon slitting machine17. February, 2025

Efficient and accurate: the core advantages and application scenarios of ribbon slitting machine17. February, 2025

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Paper Core Loading Machine

Paper Core Loading Machine Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2