What factors can cause the rewinder to get wet

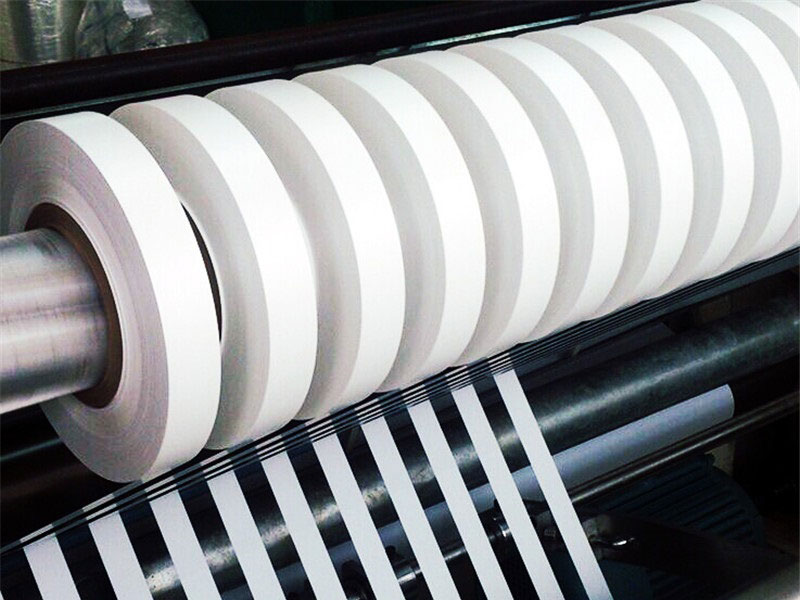

With the development of technology, the application of rewinder is becoming more and more common. Today, we will talk to you about what factors are generally caused by the rewinder when we operate the rewinder?

The device of the rewinder: After the rewinder is unpacked, the integrity of the machine should be checked, whether there is any damage in transportation, and the level of correction can be installed on a flat and solid basis after checking that there is no loss.

1. The speed ratio is not the same, and some manufacturers adopt the processing method of fine lines for noodles and large lines for interlayer in order to save costs, which also causes the problem of equipment staining paper.

2. The raw materials are not good, and the cheap semi-wood pulp shaft is used, because there are many impurities, and the phenomenon of paper staining simply occurs in the application process.

The lifting mechanism of the rewinder should be lifted smoothly, rise and fall in parallel, the bottom knife roller and the upper knife shaft should be parallel to the bottom roller, and the distance from the bottom roller should be accurate and the rolling should be flexible. After calibrating the level of the rewinder device, carefully check whether the parts are in good condition, whether the connecting bolts are tightened reliably, and whether the moving parts are flexible, and then fill the corresponding smooth oil in each smooth part, and check that the refueling is done before acknowledging that it is correct.

Recent Post

How to improve the working efficiency of slitting and rewinding machine?01. April, 2025

How to improve the working efficiency of slitting and rewinding machine?01. April, 2025 How to ensure the slitting accuracy of the slitting rewinder?28. March, 2025

How to ensure the slitting accuracy of the slitting rewinder?28. March, 2025 How about the production efficiency of the rewinder21. December, 2024

How about the production efficiency of the rewinder21. December, 2024 How to maintain the hot stamping foil slitting rewinder21. December, 2024

How to maintain the hot stamping foil slitting rewinder21. December, 2024

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Paper Core Loading Machine

Paper Core Loading Machine Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2