The reason why the knife edge presents waves and uneven slitting during the operation of the slitting machine

The slitting machine has waves at the margin during slitting, forming a high edge and low center, and the winding and rewinding will show problems such as cracks and broken belts... This condition is due to uneven marginal cuts and stacking, which is also related to the winding manipulation.

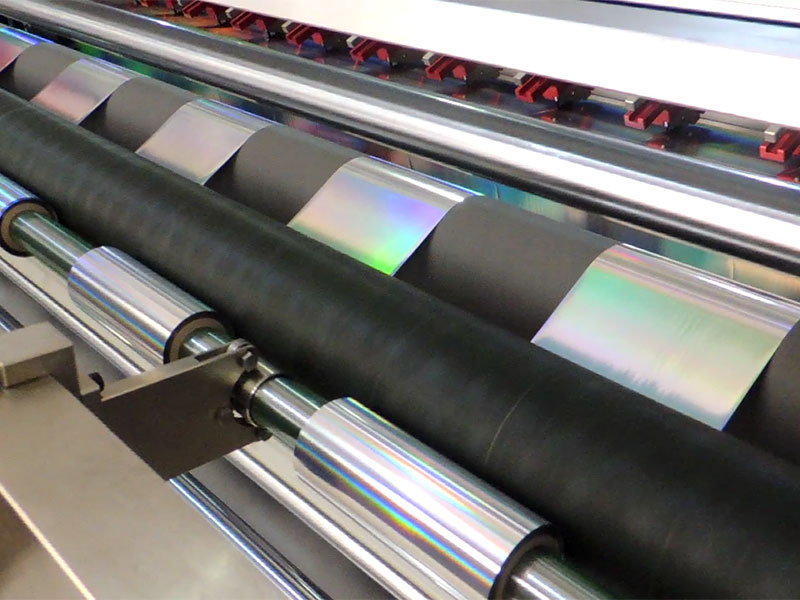

There are many reasons for this problem, which needs to be specifically analyzed, the most important of which is related to the correction before the pole piece enters the slitting part, and it is also possible that the edge of the pole piece is not neat, and the deviation correction movement is fierce during slitting, or the running speed of the pole piece of the slitting machine does not match the running speed of the slitting prop, or the knife edge of the machine may not mesh well, or the knife edge may be blunt.

If there is a wavy edge but there is no burr phenomenon that can be swept away is the phenomenon of blunt knife, the most likely is that the upper and lower knives do not match, the winding is slightly biased, and the tension control problem.

The problem of lotus margins in the material after slitting: the first point is that the hardness of the blade of the slitting machine is not good, and it will become soft after a long time of operation, which will then lead to the phenomenon of ruffles; The second point is that the slitting machine tension is not stable. In this case, it is necessary to replace the blade or adjust the tension.

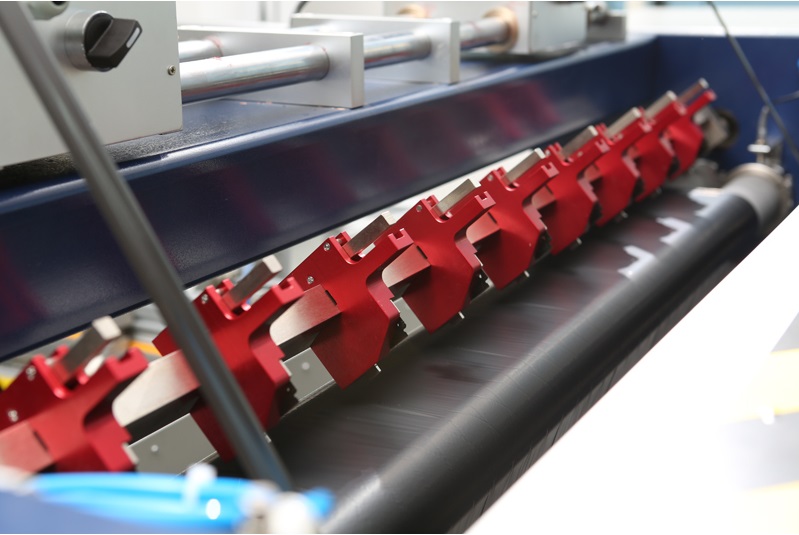

The slitter blade is one of the important components of the slitting machine equipment. If the selection is improper, the service life of the slitting blade is shortened, the slitting target requirements cannot be met, and the slitting material will have burrs and a lot of slitting chips.

Recent Post

The era of intelligent slitting: how to simplify the operation of PLC control + man-machine interface?21. April, 2025

The era of intelligent slitting: how to simplify the operation of PLC control + man-machine interface?21. April, 2025 How does a slitting machine empower multi-industry production? Inventory of core application scenarios21. April, 2025

How does a slitting machine empower multi-industry production? Inventory of core application scenarios21. April, 2025 How to use slitting machine to achieve efficient slitting and slitting of materials?21. April, 2025

How to use slitting machine to achieve efficient slitting and slitting of materials?21. April, 2025 An overview of the slitter's functions: from basic operations to advanced cutting techniques19. April, 2025

An overview of the slitter's functions: from basic operations to advanced cutting techniques19. April, 2025

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Paper Core Loading Machine

Paper Core Loading Machine Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2