17. August, 2024delish0

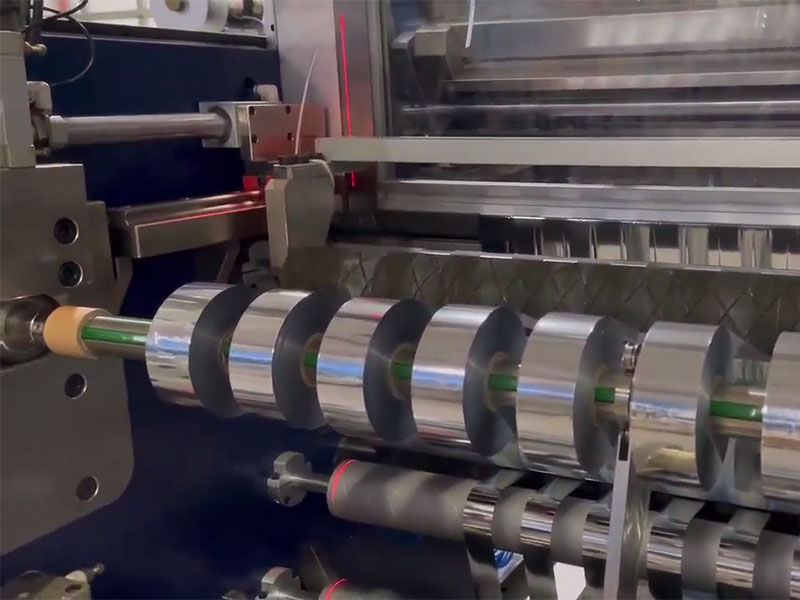

Double zero aluminum foil slitting machine is a kind of mechanical equipment specially used to cut double zero aluminum foil coils into the required width and length. It is one of the important equipment in the production process of aluminum foil, which is widely used in food packaging, pharmaceutical packaging, electronic product packaging and other fields.

The basic principle of this equipment is to cut the aluminum foil coil into different specifications of aluminum foil according to the requirements through the slitting blade. It adopts functions such as automatic feeding, automatic positioning and automatic cutting to achieve high-speed and precise cutting, thereby improving production efficiency and product quality.

The aluminum foil slitting machine is mainly composed of four parts: feeding system, cutting system, winding system and electronic control system. When working, the aluminum foil coil enters the cutting system through the feeding system, is slitted according to the set width, and then winds through the winding system. The whole process is controlled by an electronic control system to achieve automatic operation.

For the double zero aluminum foil slitting machine, the slitting accuracy is particularly important, because it directly affects the quality of the product and the production efficiency. The high-precision slitting machine can ensure that the width and length of the aluminum foil are accurate and meet the customer's requirements.

In addition, the double zero aluminum foil slitting machine usually has some special functions, such as automatic tension control, automatic deceleration and stop, automatic calculation of rewinding and unwinding diameter, etc., to further improve production efficiency and convenience of operation.

In a word, the double zero aluminum foil slitting machine plays an important role in the aluminum foil industry, which can not only meet the needs of aluminum foil cutting, but also improve production efficiency and product quality, and contribute to the development of the aluminum foil industry.

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2 Manual Paper Core Cutter

Manual Paper Core Cutter