Analysis and explanation of the main role of paper slitting machine

Paper slitting machine is used for paper slitting, in the slitting process we also have to do a good job of precision control, so that the processing of paper can be more accurate, but its role is not only these, let's talk about the main role of the paper slitting machine?

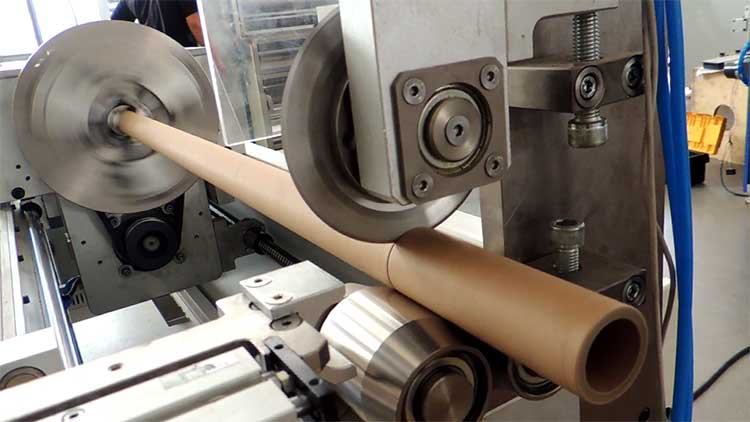

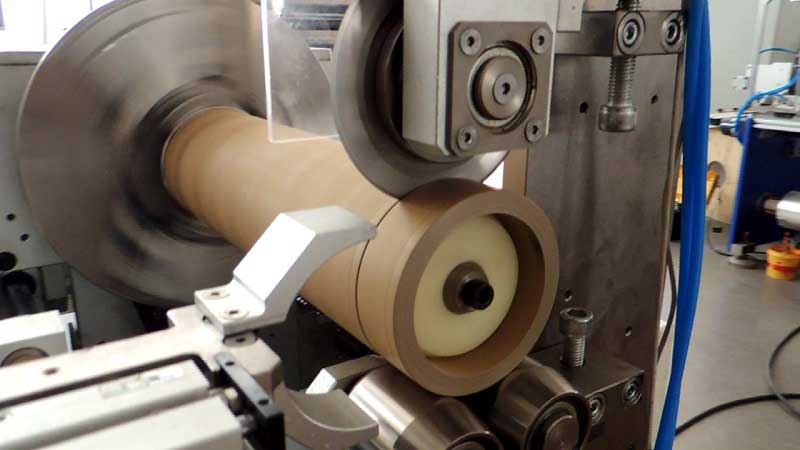

Paper slitting machine is a kind of mechanical equipment that slits wide paper or film into multiple narrow strips, and is often used in papermaking machinery and printing and packaging machinery. The traditional control scheme of the paper slitting machine is to use a large motor to drive the shaft of the rewinding and unwinding, and a magnetic particle clutch is added to the rewinding and unwinding reel, and the resistance generated by it is controlled by adjusting the current of the magnetic particle clutch to control the tension on the surface of the material. Magnetic particle clutch and brake is a special automatic actuator, which transmits torque through the magnetic particle filled in the working gap, and the magnetic state of the magnetic particle can be changed by changing the excitation current.

In turn, the transmitted torque is adjusted. It can be used for stepless speed regulation from zero to synchronous speed, and is suitable for high-speed section fine-tuning and small and medium-power speed regulation systems. It is also used to adjust the torque by adjusting the current to ensure that the tension remains constant during the winding process. The main feature of the paper slitting machine is that the magnetic particle clutch is used as a resistance device, which is controlled by the system to output a DC voltage to control the resistance generated by the magnetic particle clutch.

Recent Post

Efficient application and precision control of slitting machine in film and paper slitting28. April, 2025

Efficient application and precision control of slitting machine in film and paper slitting28. April, 2025 Detailed explanation of the multi-specification adaptation and flexible cutting function of the paper tube cutter27. April, 2025

Detailed explanation of the multi-specification adaptation and flexible cutting function of the paper tube cutter27. April, 2025 Customized paper cutting tube machine: to meet the special needs of different industries26. April, 2025

Customized paper cutting tube machine: to meet the special needs of different industries26. April, 2025 Versatile application of slitting machines: precision cutting of film, paper, metal25. April, 2025

Versatile application of slitting machines: precision cutting of film, paper, metal25. April, 2025

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Paper Core Loading Machine

Paper Core Loading Machine Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2