Explanation of the difference in the handling of different parts of the paper slitting machine

The effect of paper slitting is also different, then different parts should be used to cut the paper, which will be completed by using different slitting tools, among which razor slitting, razor slitting and crushing cutting slitting are the common three parts, let's talk about the difference between the processing of different parts of the paper slitting machine?

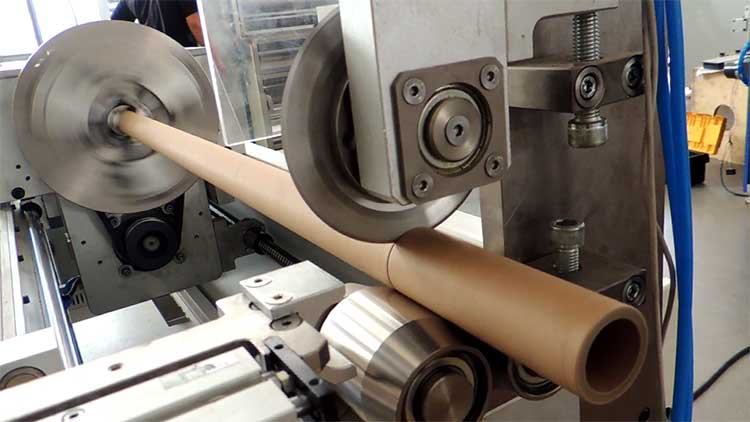

Crushing, cutting, slitting: A male knife runs against an anvil. The system is suitable for certain materials, including non-woven fabrics and foams.

Razor Slitting: This is ideal for thin plastic films, the system is very simple and quick to set up, although the razor blades are inexpensive, they need to be changed frequently to ensure high quality cut edges.

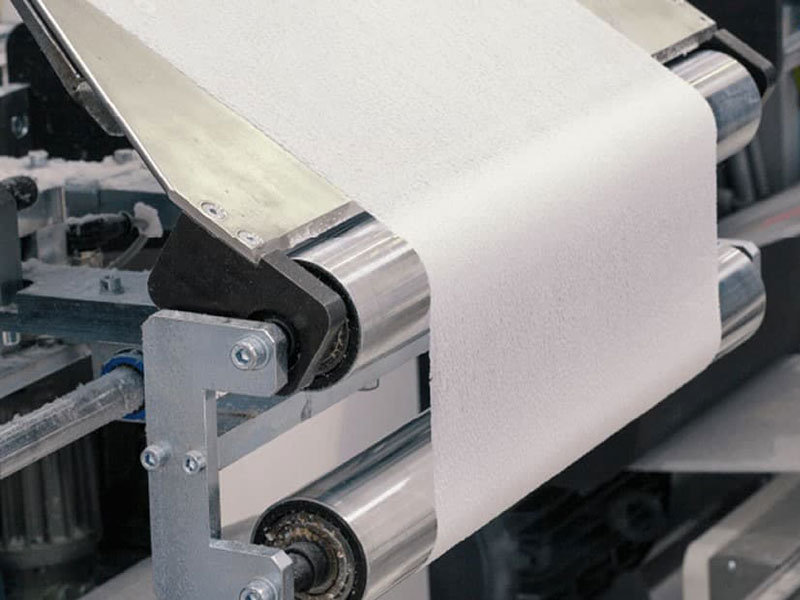

Razor slitting: round knife for scissor cutting effect, the system is widely used for paper, film and foil; Although blades take longer to position, they hold longer than razor blades, and the use of an automatic cutter positioning system reduces setup time.

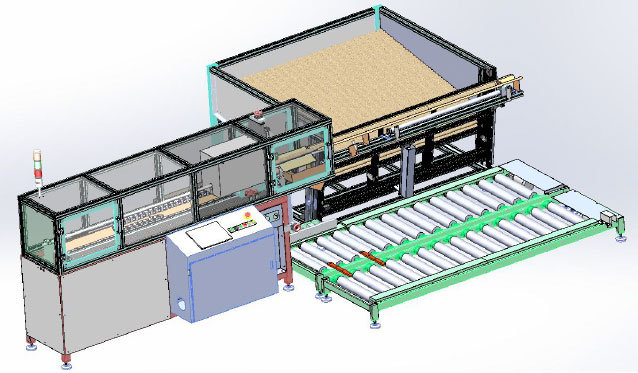

As with the slitting section, the rewinding section of the paper slitter is equally selective, the main type of which is the center winding using a differential rewind shaft. These shafts have become common on most slitter machines. The differential shaft ensures uniform tension over the entire width of the material. Utilizing feedback from the load cell, the winding tension is controlled in a closed loop, providing the total tension control system required to operate tension-sensitive materials.

Recent Post

How to choose a high-precision paper tube cutter? Guide to key parameters03. April, 2025

How to choose a high-precision paper tube cutter? Guide to key parameters03. April, 2025 Automatic paper tube cutting machine: intelligent operation and energy-saving design01. April, 2025

Automatic paper tube cutting machine: intelligent operation and energy-saving design01. April, 2025 Analysis of the advantages and application scenarios of CNC paper tube cutting machine31. March, 2025

Analysis of the advantages and application scenarios of CNC paper tube cutting machine31. March, 2025 High-efficiency paper tube cutter: a breakthrough in precision cutting technology29. March, 2025

High-efficiency paper tube cutter: a breakthrough in precision cutting technology29. March, 2025

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Paper Core Loading Machine

Paper Core Loading Machine Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2