What causes the occurrence of the slitter shaft running situation

Slitting machine is a very important equipment, we often appear slitting machine shaft running situation, so what are the general reasons for the occurrence of slitting machine shaft running?

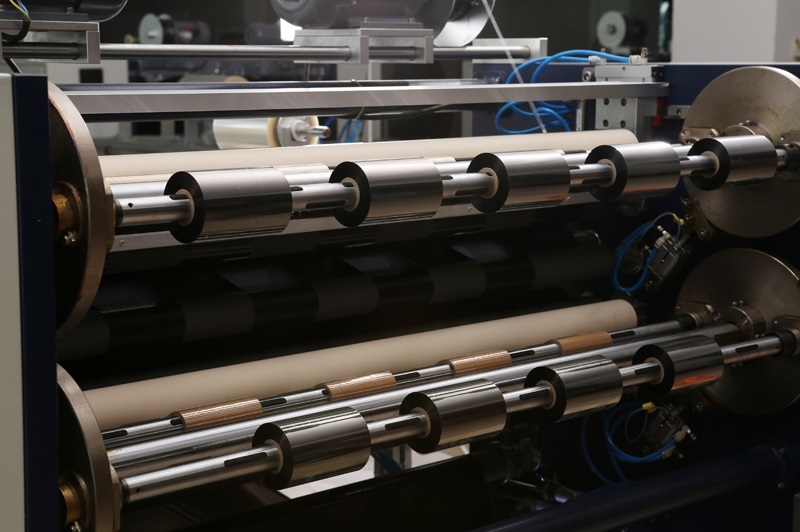

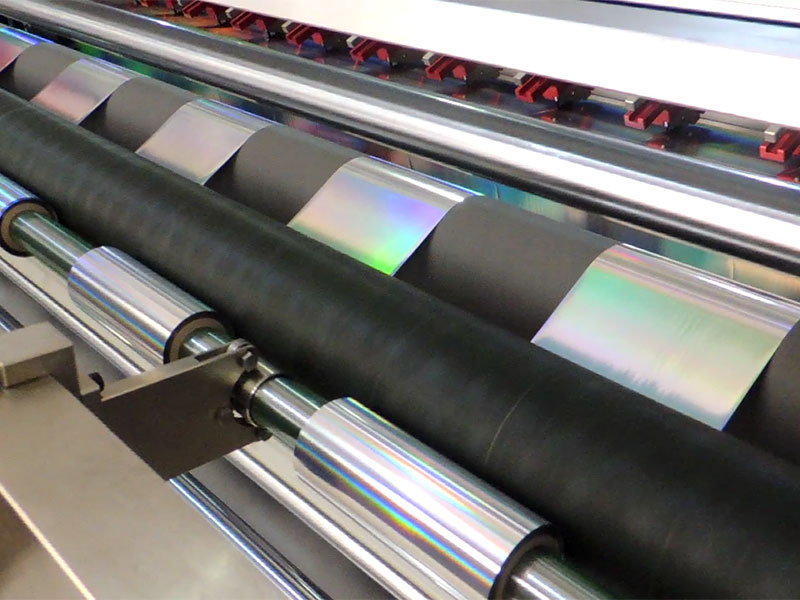

The slitter divides the film into inner and outer sides for winding, and the winding station on the inner and outer sides is mounted on the beam controlled by the hydraulic cylinder. Under the control of the hydraulic cylinder, the beam rotates back and forth within a certain angle range through the piston and connecting rod telescopic movement of the hydraulic cylinder, so as to achieve the pressure required to ensure normal winding and the purpose of loading and unloading the roll, and its automatic control process and faults are analyzed.

The working process of the slitting machine often appears that the inner and outer beams move in the direction of unwinding at the same time, so that the product in the winding moves with the unwinding direction, and finally leads to the separation of the winding pressure roller and the product, and the winding pressure is lost, resulting in the film after slitting in the outer layer of the product to run off and break the film, which cannot be produced, sometimes when the slitter is just turned on, sometimes after the slitting is rewinded to a certain length.

When we all operate and use the slitting machine, we all need to operate and use this slitting machine in the correct way, and in the case of the slitting machine running shaft, it is generally caused by the above reasons.

Recent Post

An overview of the slitter's functions: from basic operations to advanced cutting techniques19. April, 2025

An overview of the slitter's functions: from basic operations to advanced cutting techniques19. April, 2025 Industry adaptability of slitter machine: a wide range of uses from packaging to new energy19. April, 2025

Industry adaptability of slitter machine: a wide range of uses from packaging to new energy19. April, 2025 Analysis of the core functions of the slitting machine: automatic deviation correction, tension control and waste edge recovery19. April, 2025

Analysis of the core functions of the slitting machine: automatic deviation correction, tension control and waste edge recovery19. April, 2025 High-precision cutting: How does the slitting machine achieve the ultimate slitting accuracy of ±0.1mm?18. April, 2025

High-precision cutting: How does the slitting machine achieve the ultimate slitting accuracy of ±0.1mm?18. April, 2025

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Paper Core Loading Machine

Paper Core Loading Machine Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2