What factors will affect the capacity of the slitting machine

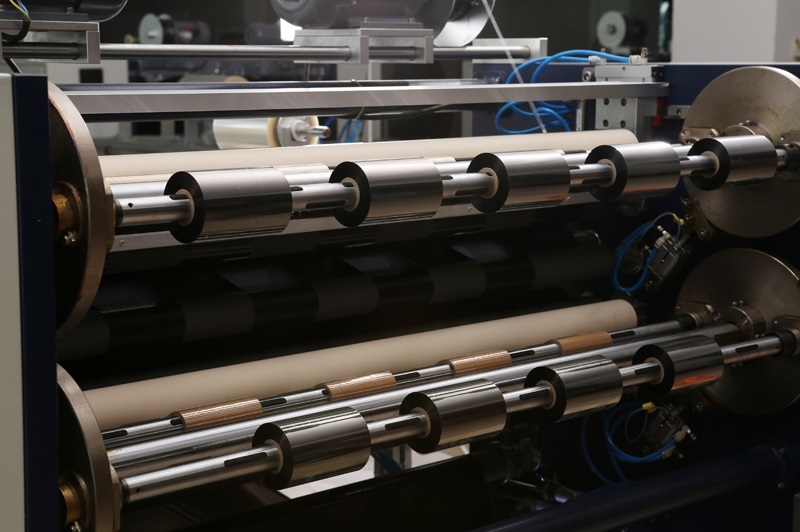

The frequency of use of slitting machine is very high, it can cut wide paper or film into a unified plan of paper or film, some paper machines or printing machines will use slitting machine. So do you know what are the main factors that determine the capacity of the slitting machine?

1. Tension control of unwinding: During the rewinding of a set of paper rolls, the rewinding tension should be avoided as much as possible to ensure that the rolling tightness of the slitting rewinder is uniform inside and outside. Secondly, in the rewinding process, if the tension control of the paper web is too small, resulting in wrinkles, intertwining of pages and other paper defects. If the tension is too controlled, it will cause bursting or damage to the paper core.

2. Line pressure of the paper roller: the paper roller pressurizes the paper roll during the rewinding process, and in the initial stage of rewinding, the paper roller provides additional load for the paper roll, and the front and rear bottom rollers act together to provide a rewinding force for the paper roll.

3. The speed difference between the front and rear support rolls: the speed difference of the support rollers forms a rewinding force, and the size of the rewinding force determines the size of the paper roll tightness, and improving the rewinding force of the slitting rewinder can increase the tightness of the paper roll Starting from these aspects.

When deciding the capacity of the slitting machine, everyone should pay more attention to the above factors, and at the same time, before the slitting machine is ready for operation, all personnel must maintain a certain safety distance from the machine to ensure personal safety before starting the operation.

Recent Post

An overview of the slitter's functions: from basic operations to advanced cutting techniques19. April, 2025

An overview of the slitter's functions: from basic operations to advanced cutting techniques19. April, 2025 Industry adaptability of slitter machine: a wide range of uses from packaging to new energy19. April, 2025

Industry adaptability of slitter machine: a wide range of uses from packaging to new energy19. April, 2025 Analysis of the core functions of the slitting machine: automatic deviation correction, tension control and waste edge recovery19. April, 2025

Analysis of the core functions of the slitting machine: automatic deviation correction, tension control and waste edge recovery19. April, 2025 High-precision cutting: How does the slitting machine achieve the ultimate slitting accuracy of ±0.1mm?18. April, 2025

High-precision cutting: How does the slitting machine achieve the ultimate slitting accuracy of ±0.1mm?18. April, 2025

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Paper Core Loading Machine

Paper Core Loading Machine Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2