Regrinding of slitter blades and maintenance of slitters

Regrinding slitter blades

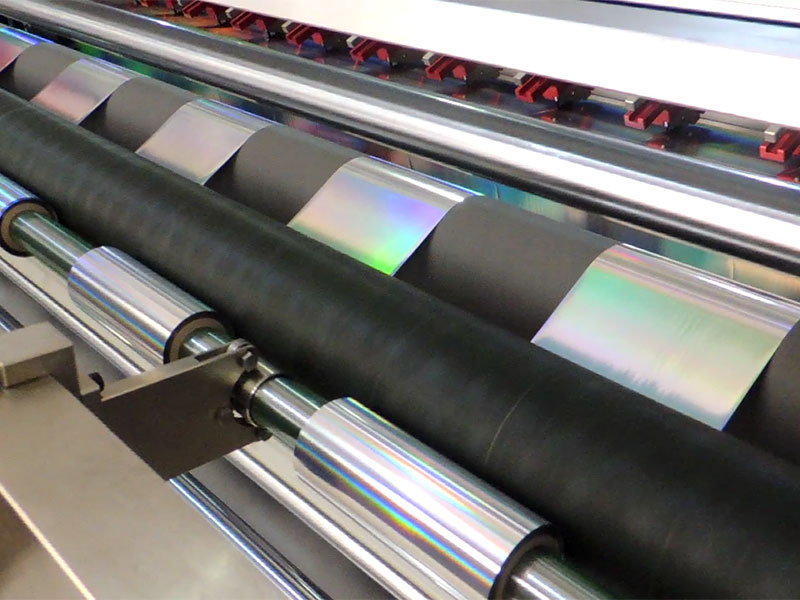

1. In the process of using the slitter blade, due to the long-term anti-extrusion with the plate, it is easy to lead to blade wear and obtuse angle, and the blade part is resistant to the extruded metal fatigue layer.

2. In order to ensure the cut quality, edge quality and dimensional tolerance of the segmented finished product, it is necessary to grind the worn blade, remove the metal fatigue layer of the knife edge, and ensure the sharpness of the knife edge.

3. In addition to the wear of the knife edge of the slitting machine blade, the outer diameter of the matching rubber ring is less worn during use.

4. If the outer diameter of the blade is relatively large after multiple wear, the rubber ring should be worn accordingly to ensure its performance, and the amount of wear depends on the outer diameter of the blade.

The whole machine maintenance of the slitting machine

1. In order to extend the overall service life of the slitting machine, the machine must be maintained.

2. The crew operator should understand the function and performance of the equipment, master the correct use method, determine the personnel and positions, and maintain the equipment regularly.

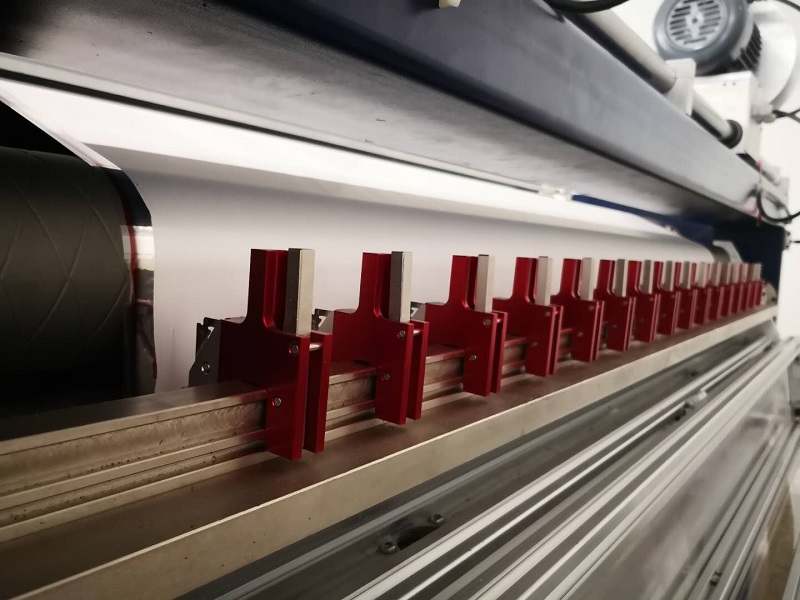

3. The slider contact surface of the slitting machine should be cleaned and oiled frequently to prevent damage to the sliding surface.

4. When disassembling and assembling the four sliders on the moving beam, they should be cleaned.

5. Only after spraying hydraulic oil on the oil pot can the lifting knife movement be carried out to prevent the burning of the sliding surface and reduce the accuracy of the equipment.

6. There is also the air filter of the DC motor fan, which should be replaced at least once every 3 days to ensure that the DC motor is well ventilated and prevent the motor from being damaged due to temperature rise during operation.

Of course, the pressure of the hydraulic pump station does not allow arbitrary adjustment. If the device fails, it should be repaired by a maintenance person.

Recent Post

An overview of the slitter's functions: from basic operations to advanced cutting techniques19. April, 2025

An overview of the slitter's functions: from basic operations to advanced cutting techniques19. April, 2025 Industry adaptability of slitter machine: a wide range of uses from packaging to new energy19. April, 2025

Industry adaptability of slitter machine: a wide range of uses from packaging to new energy19. April, 2025 Analysis of the core functions of the slitting machine: automatic deviation correction, tension control and waste edge recovery19. April, 2025

Analysis of the core functions of the slitting machine: automatic deviation correction, tension control and waste edge recovery19. April, 2025 High-precision cutting: How does the slitting machine achieve the ultimate slitting accuracy of ±0.1mm?18. April, 2025

High-precision cutting: How does the slitting machine achieve the ultimate slitting accuracy of ±0.1mm?18. April, 2025

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Paper Core Loading Machine

Paper Core Loading Machine Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2