How slitting machines maximize material utilization

In modern production, the maximum use of materials is an important issue. A slitter, on the other hand, is a machine that maximizes the use of materials, with cutting and separation technologies that minimize waste and loss. So, how to maximize the use of materials by slitting machine is discussed from the following three aspects:

1. Efficient working mode

The slitting machine has an efficient working mode that can achieve fast, continuous and precise cutting and separation. Compared with traditional manual cutting methods, it can minimize errors and waste, and improve material utilization. At the same time, it can also maximize the use of materials by adjusting cutting modes and parameters according to different material and process needs.

2. Precision control system

The slitting machine adopts a precision control system, which can realize high-precision control of various parameters and ensure the accuracy and consistency of cutting. At the same time, it can be intelligently optimized for different materials and cutting tasks, minimizing waste and losses. This sophisticated control system ensures maximum use of materials, increases productivity and reduces costs.

3. Design of human-computer interaction

The slitting machine adopts a human-computer interactive design, which can be easily adjusted and optimized by the operator. It is also equipped with a corresponding monitoring system and feedback mechanism, which can detect problems and deal with them in time. In practice, the operator can monitor the system to understand the operating status and process flow, so that the necessary adjustments and optimizations can be made to maximize the use of materials.

In summary, the slitter can maximize the use of materials through efficient working mode, precise control system and human-computer interaction design. In the future, with the continuous advancement of science and technology, the performance of the slitting machine will be optimized and upgraded to better serve the production needs of all walks of life.

Recent Post

An overview of the slitter's functions: from basic operations to advanced cutting techniques19. April, 2025

An overview of the slitter's functions: from basic operations to advanced cutting techniques19. April, 2025 Industry adaptability of slitter machine: a wide range of uses from packaging to new energy19. April, 2025

Industry adaptability of slitter machine: a wide range of uses from packaging to new energy19. April, 2025 Analysis of the core functions of the slitting machine: automatic deviation correction, tension control and waste edge recovery19. April, 2025

Analysis of the core functions of the slitting machine: automatic deviation correction, tension control and waste edge recovery19. April, 2025 High-precision cutting: How does the slitting machine achieve the ultimate slitting accuracy of ±0.1mm?18. April, 2025

High-precision cutting: How does the slitting machine achieve the ultimate slitting accuracy of ±0.1mm?18. April, 2025

Fully Automatic TTR Slitter RSDS8 Plus

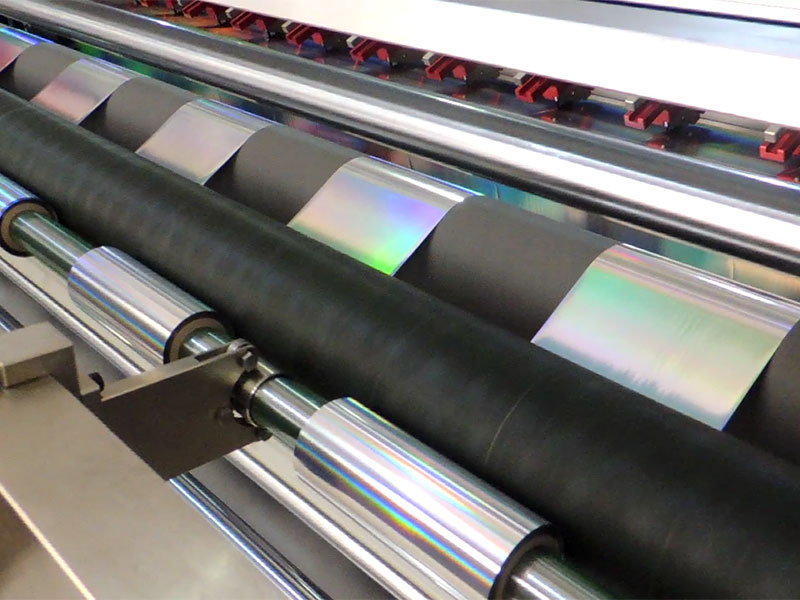

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Paper Core Loading Machine

Paper Core Loading Machine Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2