What is the technical principle of the slitting machine?

Slitting machine is a kind of equipment used to slitter materials with a large width. It has the advantages of high slitting efficiency and easy operation, and is widely used in all walks of life. So, what is the technical principle of the slitting machine?

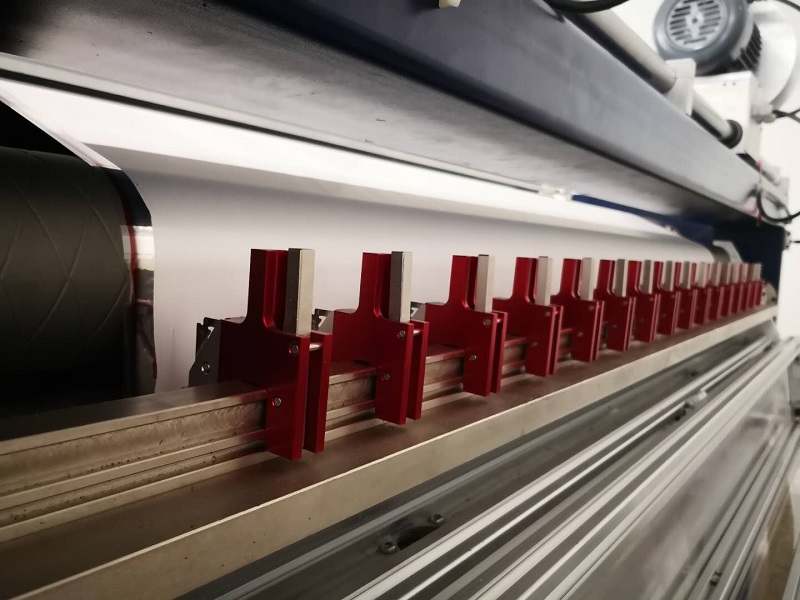

1. Slicer head structure

The heart of the slitter is the slicer head section. In the slicer head, a unique, high-precision cutting blade is used, which significantly improves the slitting accuracy. What's more, the slicer head offers seamless cuts, extremely high stability and extremely low resistance.

2. Control system

The slitting machine is also equipped with an intelligent control system, which can directly show efficient control capabilities throughout the slitting process. This system adopts PLC program control mode to achieve high-precision slitting, and has powerful data processing capabilities, making the operation more convenient.

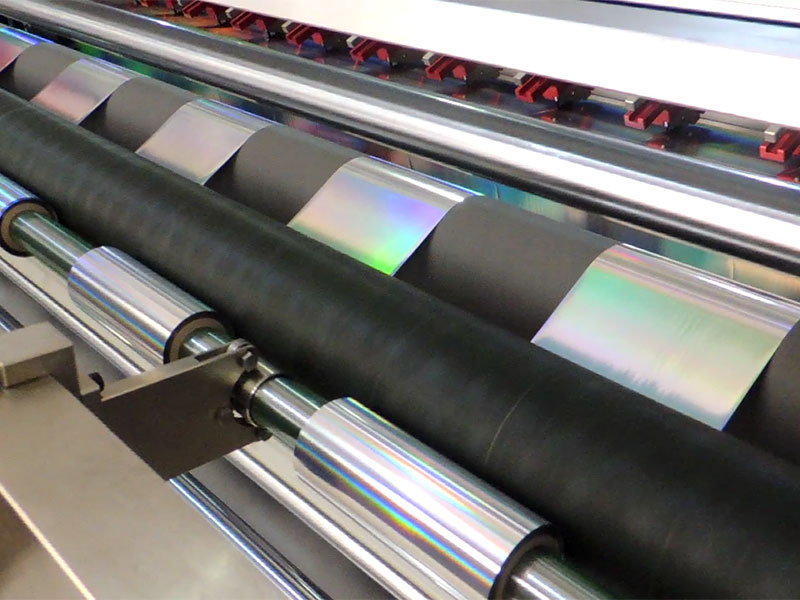

3. Processing technology

The slitter also makes use of the latest digital processing technology to ensure that the precision and speed of slitting is significantly improved. High-speed digital image processing systems provide comprehensive support for matters such as edge detection, cut control, and real-time monitoring during slitting.

conclusion

The slitting machine relies on advanced cutting technology, high-precision control system and the latest digital processing technology to achieve material slitting. Its technical principles, such as the structure of the slicer head, the application of control system and processing technology, etc., show excellent performance in slitting efficiency and slitting accuracy. With the development of production technology and automation level, slitting machines will be rapidly popularized in the future, providing strong support for the rapid development of the manufacturing industry.

Recent Post

An overview of the slitter's functions: from basic operations to advanced cutting techniques19. April, 2025

An overview of the slitter's functions: from basic operations to advanced cutting techniques19. April, 2025 Industry adaptability of slitter machine: a wide range of uses from packaging to new energy19. April, 2025

Industry adaptability of slitter machine: a wide range of uses from packaging to new energy19. April, 2025 Analysis of the core functions of the slitting machine: automatic deviation correction, tension control and waste edge recovery19. April, 2025

Analysis of the core functions of the slitting machine: automatic deviation correction, tension control and waste edge recovery19. April, 2025 High-precision cutting: How does the slitting machine achieve the ultimate slitting accuracy of ±0.1mm?18. April, 2025

High-precision cutting: How does the slitting machine achieve the ultimate slitting accuracy of ±0.1mm?18. April, 2025

Fully Automatic TTR Slitter RSDS8 Plus

Fully Automatic TTR Slitter RSDS8 Plus Hot Stamping Foil Slitter 1600mm

Hot Stamping Foil Slitter 1600mm Hot Stamping Foil Slitter (4 Shafts)

Hot Stamping Foil Slitter (4 Shafts) Paper Core Loading Machine

Paper Core Loading Machine Semi-Auto TTR Slitter RSDS2 Plus

Semi-Auto TTR Slitter RSDS2 Plus Auto Paper Core Cutter

Auto Paper Core Cutter Semi Automatic TTR Slitter RSDS5 Plus

Semi Automatic TTR Slitter RSDS5 Plus Manual TTR Slitter RSDS2

Manual TTR Slitter RSDS2